Key Features to Consider When Choosing a Fully Automatic Conveyor System

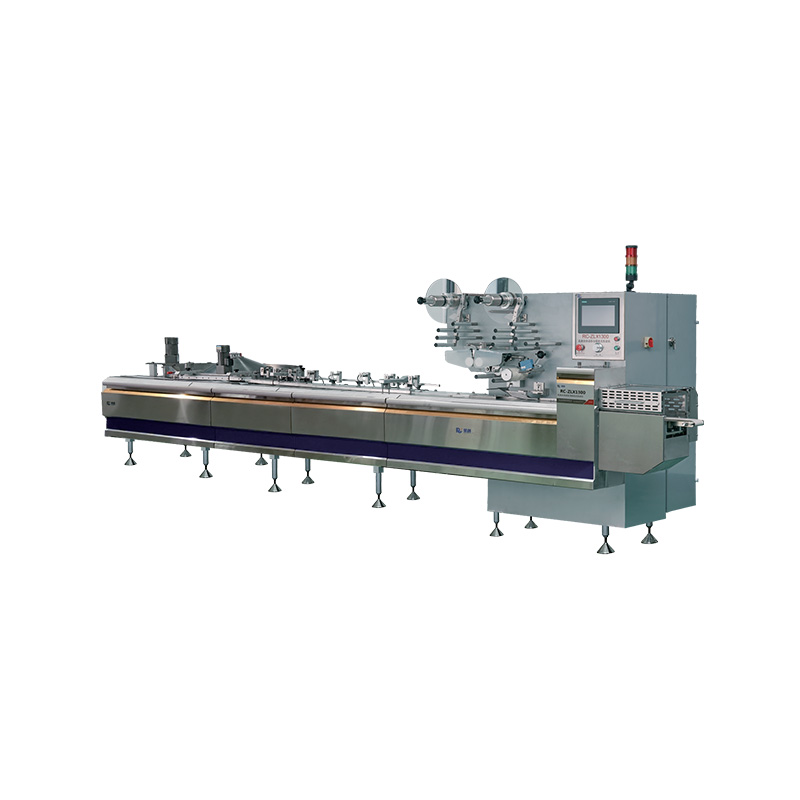

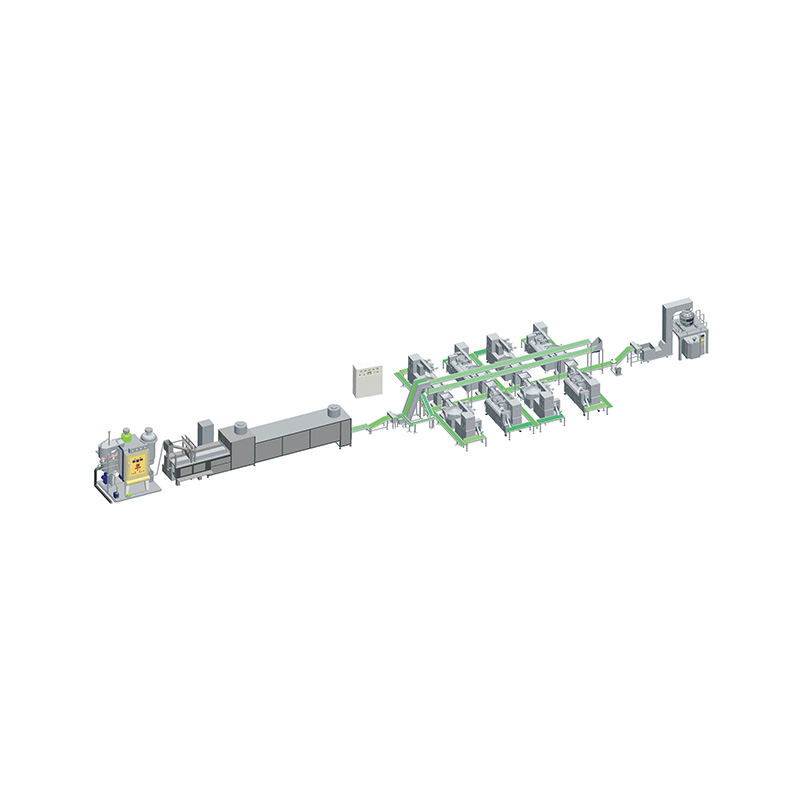

In modern production and packaging environments, efficiency and smooth material handling are essential for keeping operations running steadily. One of the systems often used to achieve this is the Fully Automatic Conveyor. These systems help move products from one point to another without manual effort, saving time and reducing the risk of handling errors. However, with so many options available, it’s important to understand the key features to look for when selecting a Automatic Conveyor for your facility.

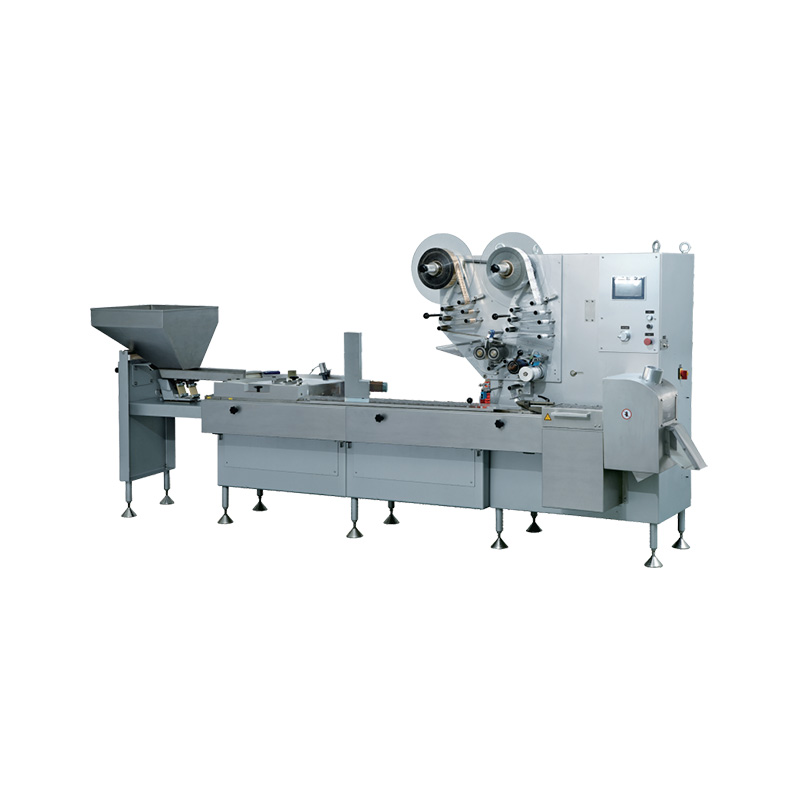

The feature to consider is the type of materials the Fully Automatic Conveyor will handle. Different industries move different products — from lightweight packaging materials to heavier industrial parts. Understanding the weight, size, and shape of the items being transported helps determine the ideal belt or chain type and conveyor design. A system built for light cartons may not perform well when handling heavy mechanical components, so careful matching of product and conveyor capacity is important.

Another important factor is the speed and throughput capacity of the Fully Automatic Conveyor. Depending on production demands, some operations may require high-speed systems to maintain workflow, while others prioritize steady and controlled movement. A conveyor’s speed range and adjustability can make a significant difference in ensuring that the system complements other equipment on the production line.

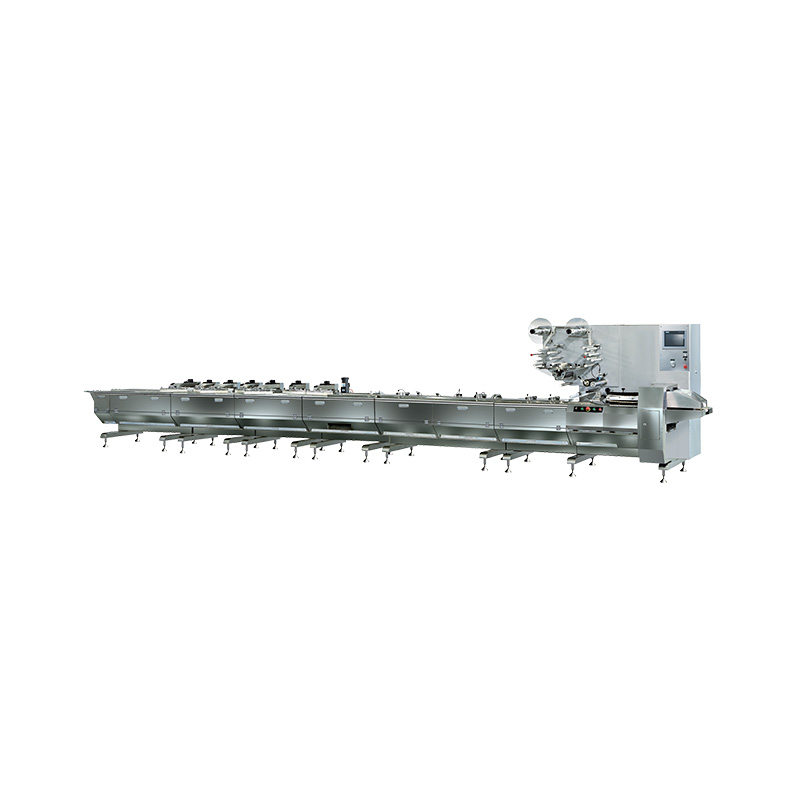

Space availability within the facility also plays a role when choosing a Fully Automatic Conveyor. Some spaces might have limited room for large systems, making compact or vertical designs more suitable. Others may need conveyors that can navigate corners, elevations, or multi-level layouts. Considering how much floor space is available and how the conveyor fits into the existing layout ensures smoother installation and future adjustments.

The control system of a Fully Automatic Conveyor is another essential feature. Modern conveyors are often equipped with programmable controls that allow operators to adjust speed, direction, and start-stop functions. The user interface should be easy to operate and integrate with other equipment, especially if the conveyor is part of a larger automated system. Reliable controls can improve safety and efficiency, reducing downtime caused by manual adjustments.

Maintenance requirements should also be considered when selecting a Fully Automatic Conveyor. Since these systems typically run for long hours, choosing a design with easy-to-access components and simple cleaning procedures can reduce interruptions. Systems that allow for quick belt changes or easy replacement of worn parts help maintain consistent operation and avoid delays.

Another factor to think about is the energy efficiency of the Fully Automatic Conveyor. As businesses aim to reduce operating costs and environmental impact, selecting systems with lower energy consumption and intelligent power-saving features can be a practical advantage. Some Automatic Conveyor systems come with automatic shut-off modes or sensors that reduce energy use when products are not in motion.

Flexibility is also valuable when considering a Fully Automatic Conveyor. Some industries may need to adjust production layouts or switch product types over time. A modular conveyor system allows for easy modifications, extensions, or reconfiguration to match future needs. This makes it possible to adapt without completely replacing the existing system.

Noise level is another feature worth attention, especially in environments where employees work nearby. A Fully Automatic Conveyor designed for quieter operation can contribute to a safer and more comfortable workplace. Checking the system’s noise specifications ensures that it fits within the acceptable limits for the production floor.

The safety features included with a Fully Automatic Conveyor are equally important. Systems should have emergency stop buttons, protective covers, and warning indicators where necessary. These built-in precautions help protect both personnel and products, reducing the likelihood of accidents or damage during operation.

Lastly, it’s helpful to consider the durability of the materials used in constructing the Fully Automatic Conveyor. Whether the system operates in a dry, humid, or dusty environment, selecting a conveyor built with materials suited to those conditions will ensure longer service life and more consistent performance.

English

English