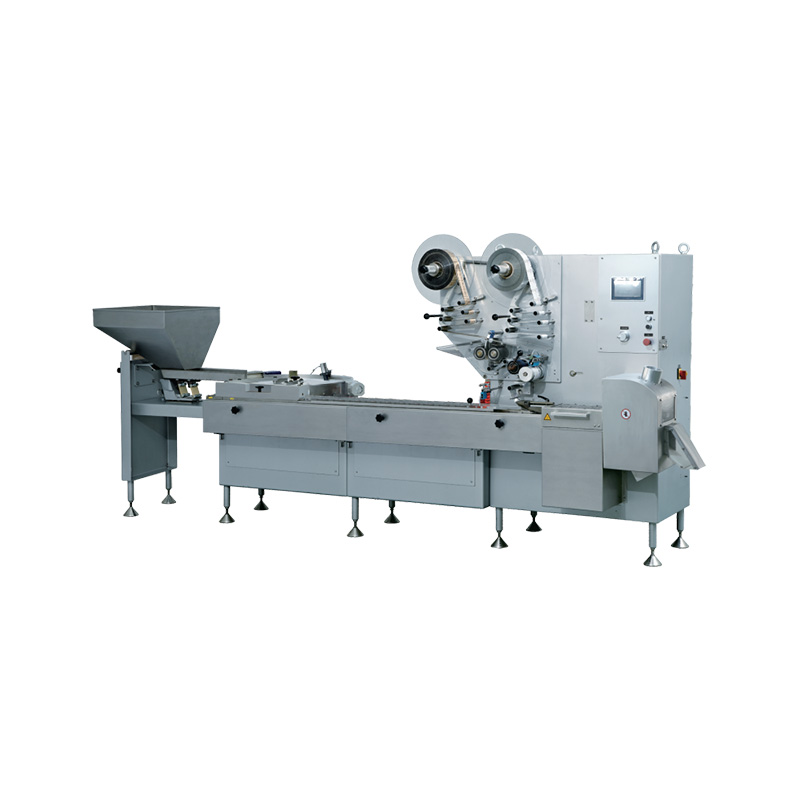

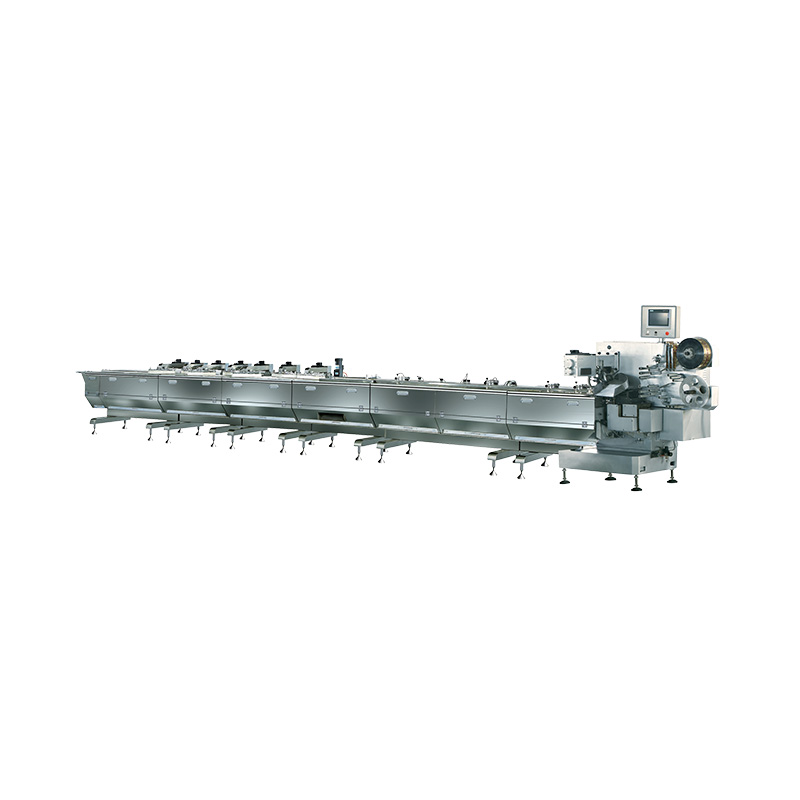

Twist Packaging Machine Tips for Smarter Material Usage

Running a twist packaging machine might seem straightforward at first glance: load the product, wrap it, twist, and move on. But any operator knows that material waste can sneak in at almost every step. Whether it's an overtwist that tears the wrapper or a slight misalignment that ruins dozens of packages, small mistakes add up quickly. The good news is that with practical strategies, you can save material, streamline your workflow, and make your production line run more smoothly.

Spot the Sources of Waste

Material waste doesn't just appear magically—it usually comes from a few predictable places. Misaligned products, inconsistent feeding, and improper machine settings are the usual suspects. Even something as simple as using the wrong wrapper roll tension can lead to excess material or rejected packages. Knowing where waste originates is the first step toward reducing it. Observing the machine in action and noting where miswraps occur will guide the improvements that matter most.

Make Your Machine Work Smarter

A twist packaging machine isn't just a box wrapper with a motor—it's a precise tool that responds to careful adjustments. Checking tension settings, feed rates, and alignment guides regularly can make a huge difference. For instance, small tweaks to the twist tightness often save more material than you might expect. A quick routine check before every shift ensures that the machine isn't overusing material or creating unnecessary scrap.

| Adjustment | How It Helps |

|---|---|

| Feed tension | Prevents overfeed and wrapper stretching |

| Product alignment | Reduces miswraps and rejects |

| Twist tightness | Saves material while maintaining secure packaging |

Keep the Workflow Smooth

Even the best machine will waste material if the production line isn't arranged logically. Place the twist packaging machine where products naturally flow to it. Avoid crisscrossing or backtracking, and group similar products together. This reduces constant changes to machine settings and cuts down on wasted wrapper. Think of it like a dance: the smoother the steps, the less likely anyone trips over their own feet.

Train Operators with Real Scenarios

Even with perfectly tuned equipment, human error can create waste. Training operators to spot common pitfalls—like misaligned packages, uneven feeds, or wrapper jams—reduces scrap and improves consistency. Encourage awareness of material use: when staff understand that every roll matters, they often take more care in operation. Quick tips, such as checking alignment before starting a batch, can prevent dozens of rejects.

Maintenance Matters

Worn rollers, loose guides, or irregular twist mechanisms don't just slow down production—they increase material waste. Establish a routine maintenance schedule to catch small issues before they turn into big problems. Inspect parts, replace components when needed, and keep everything running smoothly. This isn't just about preventing waste; it also keeps your line predictable and reliable.

Use Materials Wisely

Selecting wrappers that match the machine's capabilities is surprisingly important. Flexible materials, proper thickness, and compatible textures reduce tearing and overwrapping. The right match avoids unnecessary adjustments and ensures packages come out looking neat while minimizing excess. Even small improvements in material choice can make a noticeable difference over time.

Monitor and Learn

Keep track of scrap and identify recurring issues. Note which products, sizes, or shifts generate the most waste. Observing patterns and experimenting with small adjustments helps operators learn what works best. Simple monitoring, like a visual checklist or shift notes, creates feedback loops that gradually reduce material use without slowing production.

Avoid Common Pitfalls

Skipping calibration or alignment checks

Changing settings too frequently between products

Ignoring worn components

Failing to monitor wrapper consumption

Recognizing and addressing these issues helps production flow smoothly and reduces unnecessary losses.

Reducing material waste isn't a one-time task—it's a mindset. Encourage operators to suggest small improvements, track results, and adjust routines. Over time, even minor refinements can add up to significant savings in material, time, and effort.

Wrapping It Up

Material waste in twist packaging is more than just an expense—it's an opportunity to improve efficiency, save resources, and make your production line smarter. By observing the machine, optimizing workflow, training operators, maintaining equipment, and monitoring material use, manufacturers can minimize waste while maintaining steady output. The process is about attention to detail, small adjustments, and a willingness to continuously refine operations.

Running a twist packaging machine efficiently may take a little observation and care, but the benefits are tangible. Reduced material waste, smoother operations, and less frustration on the production line all add up. With these tips, packaging becomes not just a routine task but a streamlined, manageable process that works for both the product and the operator.

English

English