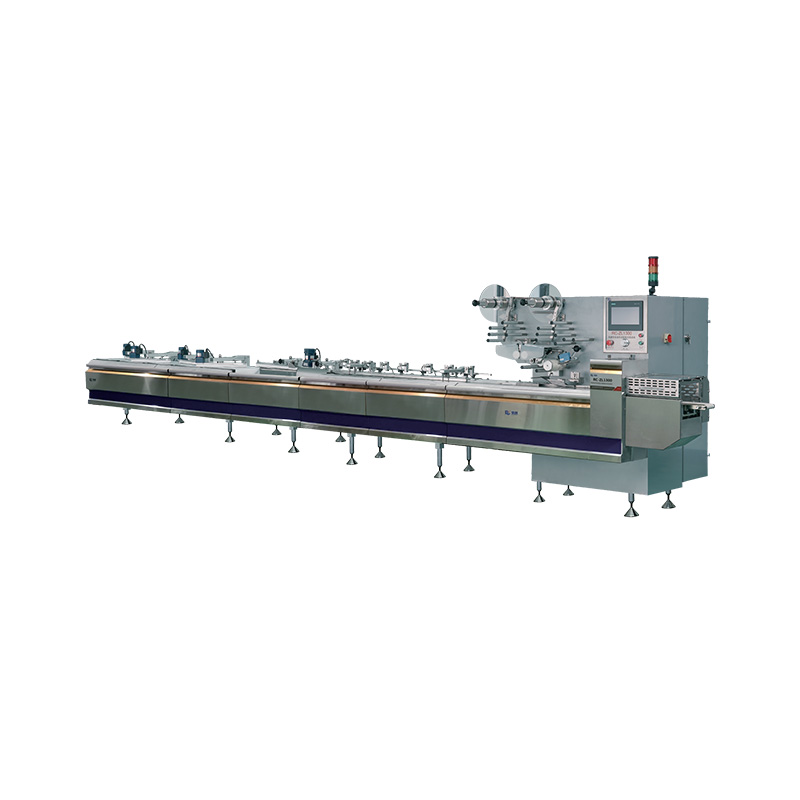

Exploring the Versatility of Fully Automatic Conveyor Systems in Modern Factories

In the rapidly evolving landscape of modern manufacturing, fully automatic conveyor systems have become indispensable for enhancing productivity and minimizing operational expenses. These systems have undergone significant evolution to meet the diverse demands of various sectors, firmly establishing themselves as a cornerstone of contemporary industrial facilities. From the transportation of raw materials to the assembly of finished products and packaging, the adaptability of automatic conveyors enables them to cater to a multitude of applications across a broad spectrum of production processes.

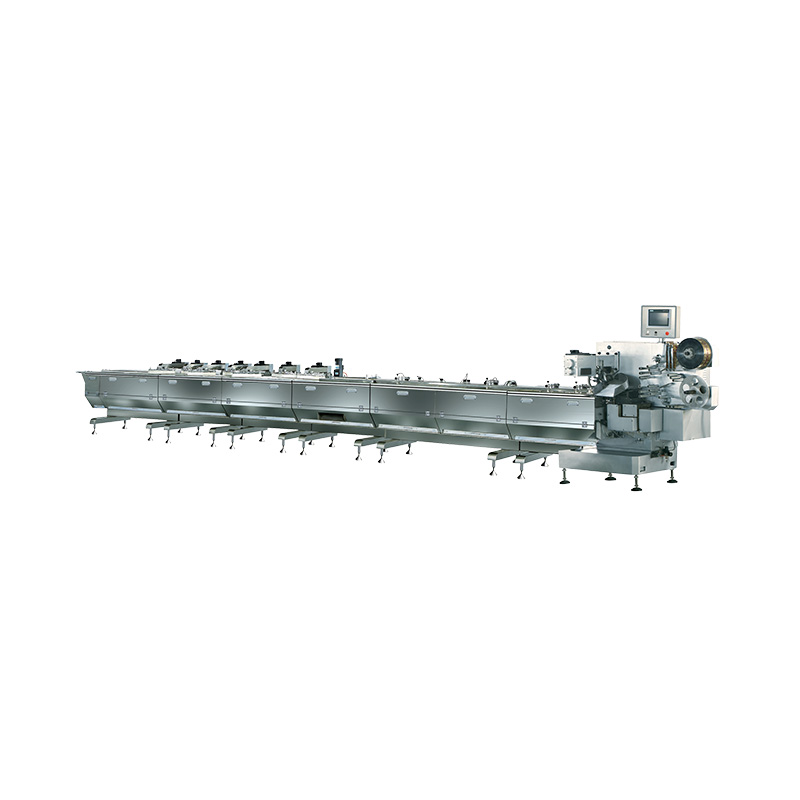

A key advantage of fully automatic conveyors lies in their capacity to accelerate production rates. In the competitive factory setting, where time is a precious commodity, the efficient movement of materials and products is paramount. These conveyor systems facilitate the seamless transfer of items, thereby diminishing the time required for manual handling. For instance, in the fast-paced and hygiene-sensitive food processing sector, automatic conveyors can swiftly shuttle ingredients through different stages of production, ensuring a smooth and uninterrupted workflow.

Furthermore, fully automatic conveyors enhance operational consistency and error reduction. Unlike manual labor, which is susceptible to fatigue and human error, conveyors maintain a high degree of precision in their operations. This ensures that items are consistently transported, thereby reducing the risk of errors such as misaligned components or incorrect packaging. In industries where precision is paramount, such as electronics manufacturing, automatic conveyors guarantee that each product reaches its designated destination at the precise moment required.

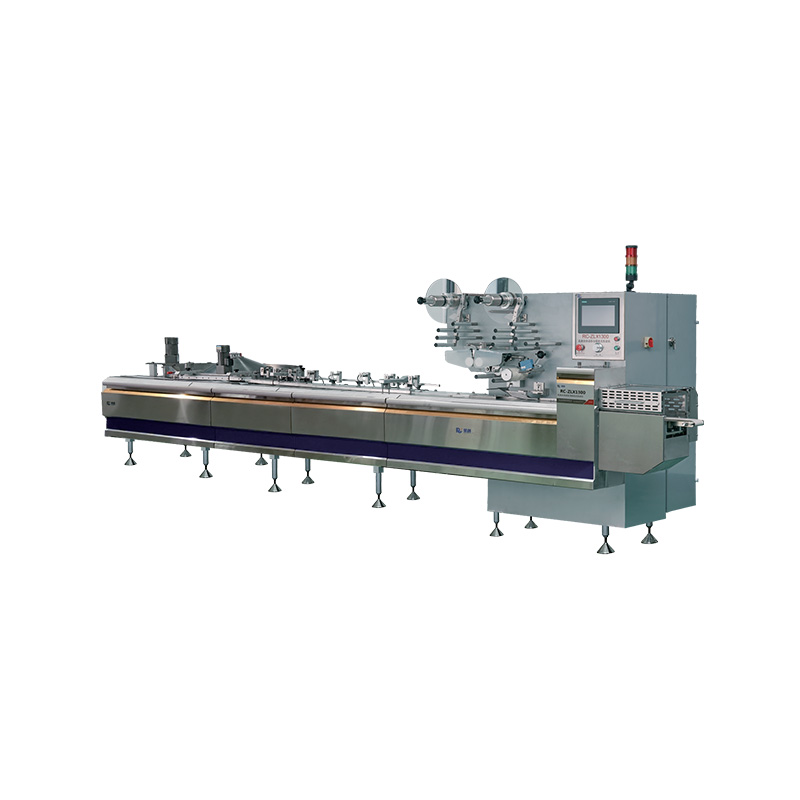

The flexibility of Fully Automatic Conveyor systems also makes them adaptable to a variety of factory layouts. Whether the factory operates in a straight line, a loop, or requires specialized configurations, conveyors can be customized to fit the available space and production process. Conveyors can curve, incline, or even switch directions depending on the specific needs of the production line. This adaptability helps factories optimize their use of space, making even smaller or more complex layouts work efficiently.

In modern factories, where different production processes often happen in parallel, Fully Automatic Conveyor systems can help maintain smooth coordination between various stages of production. For instance, in a factory that produces multiple product types or runs different production schedules, conveyors can be programmed to adjust to different workflow requirements.

Safety is another area where Fully Automatic Conveyor systems offer substantial benefits. Factories can be hazardous environments, with risks ranging from heavy lifting to exposure to moving machinery. By automating the transport of materials, these conveyors reduce the need for workers to interact with dangerous processes, thus lowering the risk of workplace accidents.

Fully automatic conveyor systems not only bolster workplace safety but also significantly improve ergonomic conditions. The manual handling of materials, particularly heavy items, can result in repetitive strain injuries due to the frequent lifting required. By integrating a conveyor system, employees are liberated from such physically demanding tasks and can instead concentrate on more specialized roles, such as quality assurance and machinery operation.

The maintenance and reliability of conveyor systems are paramount for maintaining a smooth production process. Fully automatic conveyor systems are engineered to reduce downtime, ensuring continuous operation. Many contemporary conveyors come equipped with user-friendly maintenance features, including easy access to components and automated diagnostic systems that can anticipate maintenance needs. This proactive maintenance strategy is crucial for sustaining ideal performance and preventing costly production interruptions.

Energy efficiency has become a critical consideration for factories aiming to cut operational expenses. A well-crafted fully automatic conveyor system can be a key player in achieving energy savings. Some systems incorporate energy-efficient motors and sophisticated control systems that adjust the conveyor's speed in response to the load, thereby conserving energy when the production line is not operating at full capacity. These energy savings can accumulate over time, rendering the conveyor system more economically viable in the long term.

English

English