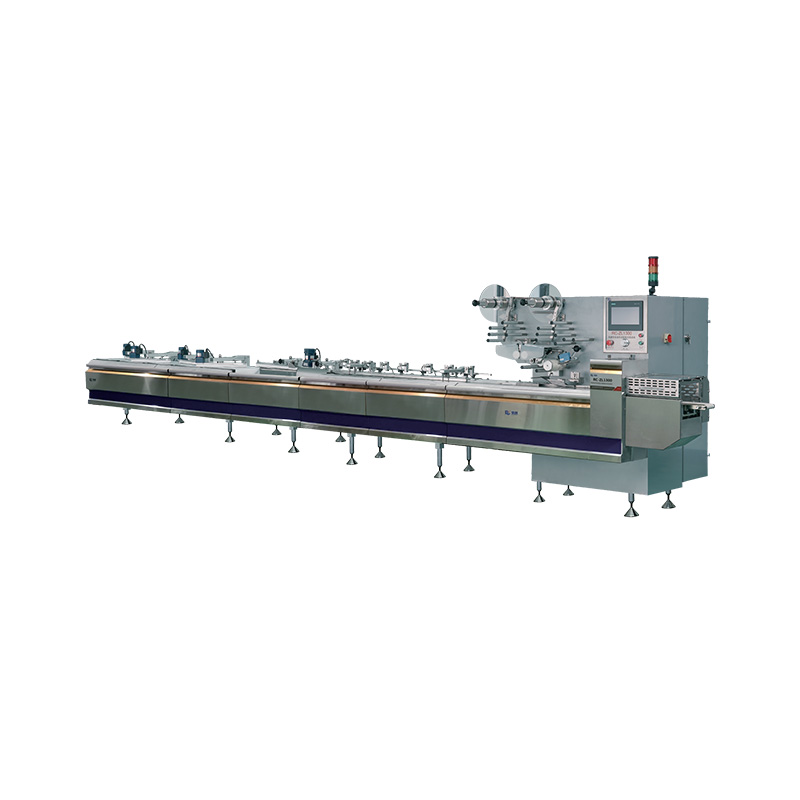

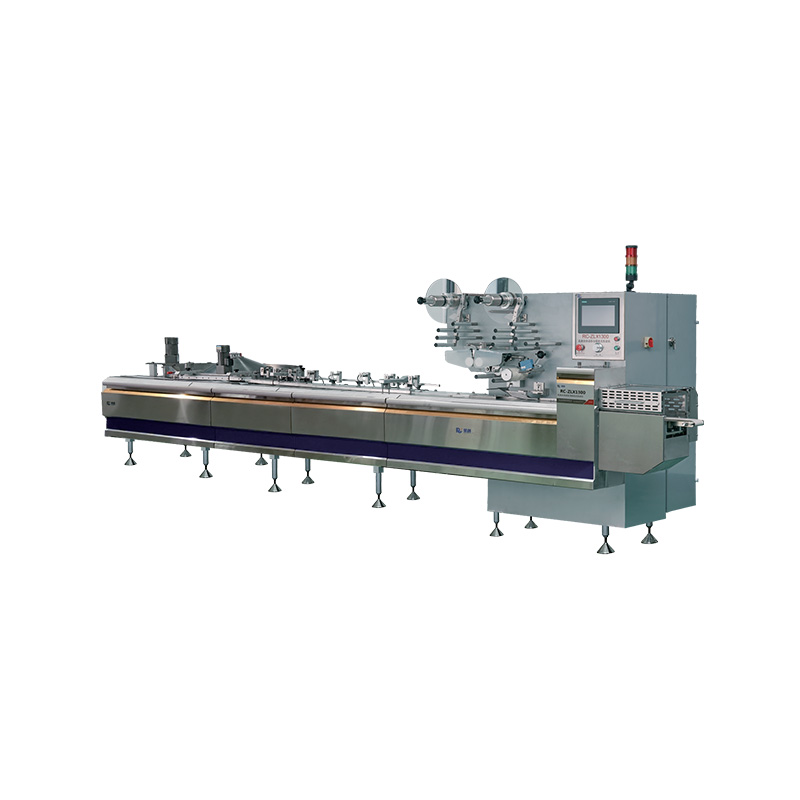

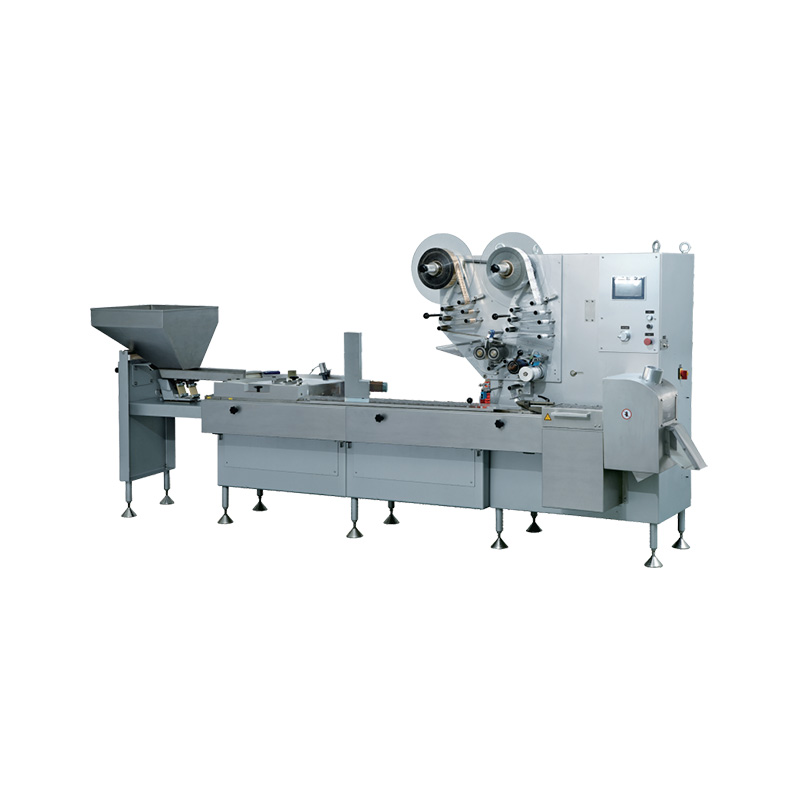

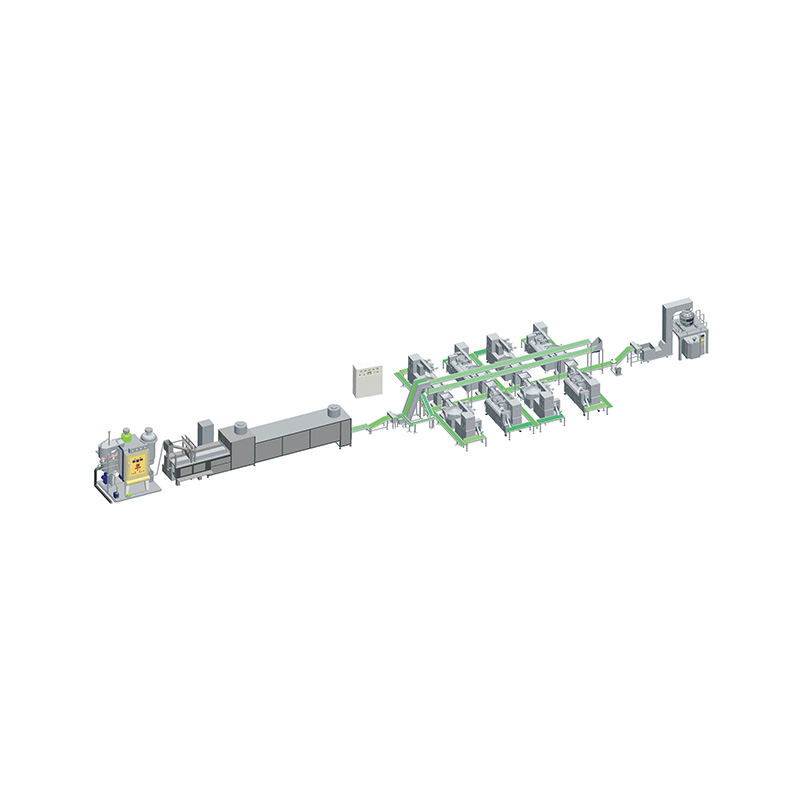

The Fully automatic multifunctional conveying production line RC-SCX1500 is a comprehensive and advanced system designed for the candy industry. This production line integrates various processes including melting, mixing, vacuum film cooking, automatic ingredient dosing, coloring, and molding. It can produce candy through pouring or by using a hard candy forming machine that extrudes, stamps, and rolls the candy into pellets. These are then automatically conveyed to single-twist, double-twist, or pillow packaging machines, and finally to multi-head weighing machines for vertical automatic large bag packaging. The entire process, from initial molding to secondary, tertiary, and quaternary packaging, is seamlessly integrated into this fully automatic candy conveying production line.

-

Description

The RC-SCX1500 Fully Automatic Multifunctional Conveying Production Line is a state-of-the-art solution designed to automate and streamline material handling in industrial environments. This versatile production line is engineered for optimal efficiency, providing seamless operation and flexibility in various sectors, from manufacturing to logistics and beyond.

Key Features:

Fully Automated Operation: The RC-SCX1500 is equipped with advanced automation, reducing human intervention and enhancing operational efficiency. It features precise control systems that ensure smooth and reliable material handling.

Multifunctional Capabilities: This production line supports a variety of functions such as conveying, sorting, loading, and unloading, making it a versatile choice for diverse industrial applications.

High-Speed Performance: Designed to handle high-throughput operations, the RC-SCX1500 can process materials quickly and efficiently, improving overall production time and reducing delays.

Flexible Configuration: The production line can be tailored to meet specific operational needs, with customizable conveyor lengths, speeds, and material handling options to suit a wide range of industries.

Durable Construction: Built with high-quality materials, the RC-SCX1500 is durable and reliable, designed to withstand the demands of continuous operation in tough industrial environments.

User-Friendly Interface: The system comes with an intuitive control panel that makes it easy for operators to monitor and adjust settings as needed, ensuring smooth and hassle-free operations.

Energy-Efficient Design: The RC-SCX1500 features energy-efficient components that help reduce operational costs while maintaining high productivity levels, making it a sustainable choice for businesses.

Safety and Compliance: Designed with safety in mind, the RC-SCX1500 includes safety features to protect workers and ensure compliance with industry standards.

Applications:

The RC-SCX1500 Fully Automatic Multifunctional Conveying Production Line is ideal for industries such as:

Manufacturing: For assembly lines, packaging, and material handling.

Logistics: For sorting and transporting goods in warehouses and distribution centers.

Food and Beverage: For automated material handling in food processing and packaging lines.

Pharmaceuticals: For efficient handling of raw materials and finished products in pharmaceutical manufacturing.

-

Parameter

Zhejiang Rongchuang Intelligent Technology Co., Ltd. is a professional customized and automated food machinery manufacturer integrating R&D, manufacturing, sales, customer service, equipment import and export, and provides a full set of automation solutions for food machinery and turnkey intelligent technology projects. We supply RC-SCX1500 Fully automatic multifunctional conveying production line manufacturing and custom RC-SCX1500 Fully automatic multifunctional conveying production line exports.

The company's core team has 25 years of professional technical experience in the food machinery automation industry. It has successfully established several machinery and equipment factories in Shanghai, Guangdong, Fujian, and Zhejiang, with a total investment of approximately RMB 218 million.

The Rongchuang brand mainly produces a series of intelligent equipment such as pillow packaging machines, bag packaging machines, vertical packaging machines, double and single twist packaging machines, and a full set of solutions for conveying automation production lines.

With 25 years of industry technical experience and continuous exploration and progress, Rongchuang people insist on market and product innovation as the guide, and introduce advanced packaging equipment and technology, processing centers and testing instruments in Europe and the United States. The company adheres to the management model of 5s management, standardization, standardization, and intensiveness. "Rongchuang" is a win-win situation, and dares to create people first. Rongchuang people adhere to the spirit of integrity, responsibility, innovation and dedication, and take improving production efficiency, reducing production costs and enhancing corporate competitiveness as their mission. They continue to provide high-speed and efficient automated production intelligent equipment as well as a complete after-sales service system and technical support for the development of many food companies.

-

In today’s manufacturing environment, efficiency and reliability are key factors that drive success. A vertical packaging machine factory has recently implemented a series of advanced automation techn...

READ MORE -

In the modern industrial world, automation plays a pivotal role in streamlining operations and improving overall efficiency. One significant advancement in automation is the fully automatic conveyor s...

READ MORE -

In recent years, the packaging industry has been undergoing rapid transformation. With the rise of global e-commerce, food delivery services, and retail distribution, the demand for efficient and reli...

READ MORE -

Running a twist packaging machine might seem straightforward at first glance: load the product, wrap it, twist, and move on. But any operator knows that material waste can sneak in at almost every ste...

READ MORE -

The flow pack machine has become a popular solution for packaging these types of products due to its ability to maintain product integrity while speeding up the packaging process. Flow pack machines a...

READ MORE

English

English