What is Fully Automatic Conveyor and How It Works

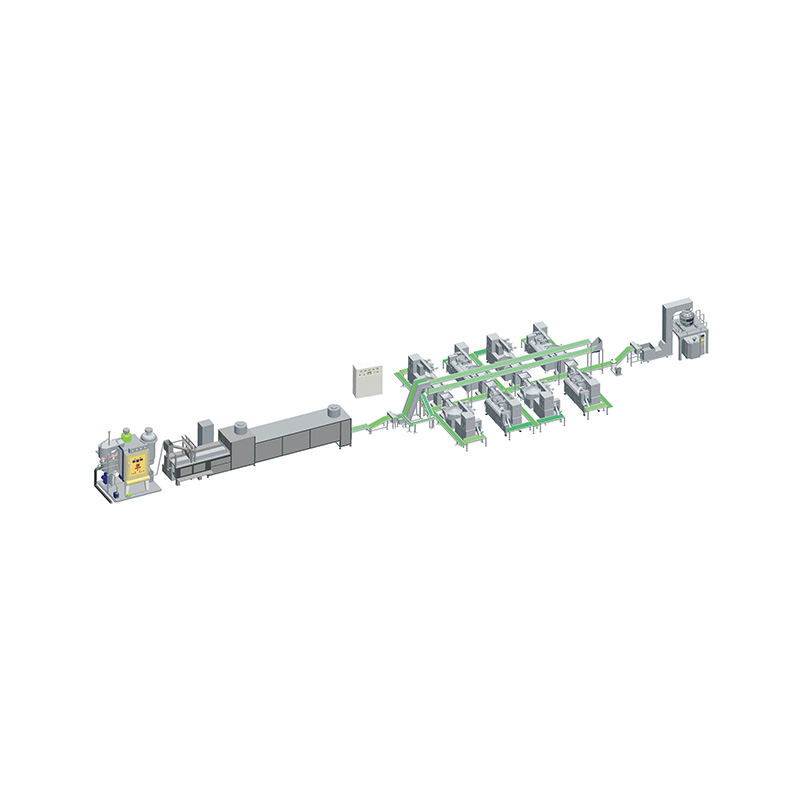

In the modern industrial world, automation plays a pivotal role in streamlining operations and improving overall efficiency. One significant advancement in automation is the fully automatic conveyor system, which is a key component in various sectors, from manufacturing to logistics. These conveyors move materials seamlessly through production lines or distribution systems with minimal human intervention.

What is a Fully Automatic Conveyor?

A fully automatic conveyor is a type of material handling equipment designed to move items from one location to another without the need for continuous human involvement. Unlike manual or semi-automatic systems, it relies on advanced components such as sensors, control panels, and electric motors to manage the transportation process with precision. These elements work together to regulate speed, detect product position, and ensure smooth transitions between different stages of production or distribution.

The primary purpose of a fully automatic conveyor is to create a consistent flow of goods within a facility, whether it involves raw materials entering the production line, semi-finished items moving between workstations, or packaged products being transferred to storage or shipping areas. This seamless movement reduces downtime, limits manual handling, and supports a more structured workflow.

Such systems are highly adaptable, which allows them to be used in a wide range of industries. In manufacturing, they may be configured to handle heavy components, while in food or pharmaceutical settings, they are often designed with hygienic surfaces and easy-to-clean structures. Because of this versatility, Fully Automatic Conveyor have become an integral part of modern industrial infrastructure, ensuring that operations remain consistent, safe, and resource-efficient.

Key Features

Fully Automatic Conveyor come with several important features that make them suitable for a wide range of industries. Below is a summary of the key characteristics:

| Feature | Description |

|---|---|

| Automation | Operates autonomously, reducing the need for manual labor while increasing consistency. |

| Advanced Sensors | Equipped with sensors to detect the position of materials and adjust their movement accordingly. |

| Variable Speed Control | Adjusts speed automatically based on real-time conditions to enhance operational efficiency. |

| System Integration | Easily integrates with other systems, such as robots or machines, for smooth and continuous operation. |

| Modular Design | Allows for customization based on specific requirements, adapting to different industries. |

| Durability | Built to handle demanding environments, ensuring long-lasting and reliable performance. |

Benefits

Fully Automatic Conveyor offer several advantages that can help businesses enhance productivity, reduce costs, and improve safety. The following points highlight some of these benefits:

1.Enhanced Productivity

By reducing the need for manual labor, Fully Automatic Conveyor allow for faster processing times. The automation of material transport increases throughput and optimizes resource utilization.

2.Cost Efficiency

With fewer workers required to manage material handling, companies can save on labor costs. Additionally, the efficiency of automatic conveyors helps minimize material waste, leading to potential cost savings.

3.Improved Safety

Fully Automatic Conveyor reduce the need for workers to manually transport heavy or hazardous materials, decreasing the risk of injuries. Automation also minimizes the possibility of human error, making the system safer to operate.

4.Consistency and Precision

These conveyors ensure that materials are transported without deviation, maintaining accuracy in production and reducing errors that may occur with manual handling.

5.Space Optimization

Automatic conveyors are often designed to be compact, allowing them to fit into areas with limited space. This is especially important in industrial environments where space is at a premium.

Applications

Below are some of the key applications:

1. Manufacturing

Automatic conveyors are used to transport raw materials, components, or finished products along the production line. They help reduce downtime, increase production speeds, and ensure smooth transitions between workstations.

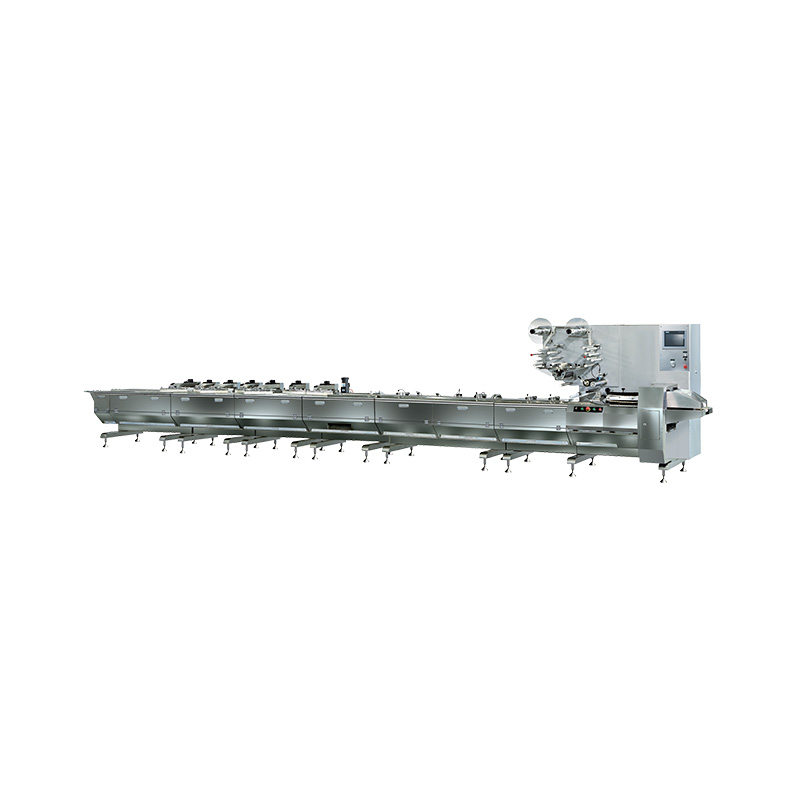

2. Packaging

In packaging industries, automatic conveyors help move items between sorting, filling, and packaging stations. They streamline the packaging process by reducing handling times and improving overall throughput.

3. Food Processing

The food industry relies on automatic conveyors to move ingredients, raw materials, and finished goods. These conveyors are built to meet the industry’s hygiene standards, with features that allow for easy cleaning and maintenance.

4. Logistics and Warehousing

Automatic conveyors are widely used in warehouses to move and sort packages. They help speed up order fulfillment and improve accuracy by reducing manual labor in sorting and packaging tasks.

5. Pharmaceuticals

The pharmaceutical sector uses automatic conveyors to transport raw materials, drugs, and packaging. Given the importance of maintaining strict regulatory compliance, these conveyors are often designed with features to prevent contamination and ensure safe handling.

Types of Systems

There are various types of Fully Automatic Conveyor, each designed for specific material handling needs. Here are some of the most common types:

1.Belt Conveyors

Belt conveyors use a continuous loop of material to move goods from one point to another. They are widely used for lightweight to medium-weight items and are commonly found in production and packaging lines.

2.Roller Conveyors

Roller conveyors are made of a series of rollers that transport materials across a surface. They are suitable for heavier loads and are commonly used in warehouses or industrial settings.

3.Pneumatic Conveyors

Pneumatic conveyors use air pressure to move materials through enclosed tubes. They are ideal for handling bulk materials, such as powders and granules, and are often used in industries like food processing and chemicals.

4.Chain Conveyors

Chain conveyors use a chain to transport goods, particularly those that are heavy or require special handling. They are often used in industries like automotive manufacturing and material handling.

5.Spiral Conveyors

Spiral conveyors are designed to transport materials vertically or along tight curves. These are useful in applications where space is limited but high throughput is still required.

How They Improve Industry Operations

Fully Automatic Conveyor provide several operational advantages that improve productivity and efficiency in industries:

Increased Production Speed: Automation speeds up the transportation of materials, which helps shorten production cycles.

Error Reduction: With minimal human involvement, the likelihood of errors due to fatigue or inattention is greatly reduced.

Flexibility: Automatic conveyors can be adjusted in terms of speed, path, and capacity, allowing industries to meet changing production needs without major adjustments.

Predictive Maintenance: Many modern systems feature predictive maintenance capabilities, which can forecast issues before they cause significant disruptions, thus ensuring minimal downtime.

Fully Automatic Conveyor are vital components in modern industrial environments, offering numerous advantages such as improved productivity, safety, and cost efficiency. These systems enhance material handling processes, reduce manual labor, and ensure smooth, continuous operations. Whether in manufacturing, logistics, food processing, or pharmaceuticals, Fully Automatic Conveyor provide industries with the tools to streamline their operations and increase overall efficiency.

As technology continues to advance, the capabilities of these systems will only improve, helping businesses to further optimize their production processes. By embracing automation, industries can ensure their long-term success and competitiveness in an increasingly automated world.

English

English