Our High Speed Fully Automatic Multifunctional Pillow Packaging Machine RC-ZL1300 is engineered for efficiency, boasting a maximum speed of 1300 units per minute. It's designed to streamline the packaging process for candies and other solid, regularly shaped items.

-

Description

-

Parameter

Model model: RC-Z1300 Packaging speed: 50-1300pcs/min Packaging size: 15-60mm Shape of packages: Round sheet, sphere, oval, waist round, cylindrical, etc. Total power: 6kw Outside dimensions: 2876*1200*1700mm Total weight: 1150kg Power supply: 380v 50Hz Packaging materials: OPP, CPP, PET aluminium-plated film, aluminium-plastic film, paper-plastic, paper-adhesive and other single-layer and multi-layer heat-sealable materials. Designed for versatility, the RC-Z1300 accommodates a range of packaging sizes, including round sheet, sphere, oval, waist round, and cylindrical shapes. Whether you are packing food, pharmaceuticals, or consumer goods, this machine guarantees packaging that meets high-quality standards while optimizing your production efficiency.

Key Features of the RC-Z1300 High-Speed Fully Automatic Pillow Packaging Machine

1. High-Speed Operation

The RC-Z1300 is engineered for speed and efficiency, capable of packaging 50 to 1300 units per minute. This makes it an ideal solution for businesses looking to scale up their production, reducing the time needed for packaging while maintaining consistent product quality.

2. Versatile Packaging Sizes and Shapes

This machine is designed to handle multiple packaging shapes, including round sheets, spheres, ovals, waist rounds, and cylindrical shapes, making it adaptable to various products. It can easily adjust to packaging different types of goods, ensuring flexibility in your production line.

3. Compatible with Multiple Packaging Materials

The RC-Z1300 can process a wide range of packaging materials, such as:

OPP, CPP, PET aluminium-plated film

Aluminium-plastic film

Paper-plastic and paper-adhesive films

Single-layer and multi-layer heat-sealable materials

This wide compatibility with various materials allows businesses to select the best packaging film that suits their products and branding needs.

4. Precise Packaging with Advanced Technology

Built with advanced servo motor and PLC control technology, the RC-Z1300 ensures precise cutting, sealing, and packaging. The machine’s high accuracy reduces material waste and enhances packaging consistency, resulting in better product presentation and reduced operational costs.

5. Efficient Power Usage

The RC-Z1300 operates with a total power requirement of 6 kW and uses a 380V 50Hz power supply, making it energy-efficient while delivering high-speed performance. The machine's design focuses on balancing power consumption with output to help keep operational costs low.

6. Compact Design and Robust Construction

With a compact size of 2876mm x 1200mm x 1700mm and a total weight of 1150kg, the RC-Z1300 fits into most production lines, optimizing space while maintaining its robustness. The solid construction ensures durability and longevity, reducing the need for frequent maintenance.

7. User-Friendly Control System

The RC-Z1300 comes equipped with a user-friendly touch screen interface that allows operators to easily set parameters, monitor production status, and make adjustments in real-time. This intuitive control system ensures minimal training time for operators and reduces errors in the packaging process.

Applications of the RC-Z1300

The RC-Z1300 is perfect for industries that require high-speed packaging of solid, regularly shaped items. Its key applications include:

Candy Packaging: Ideal for packaging candies, chewing gum, and other confectioneries.

Snacks: Suitable for packaging a variety of snacks, including chips, biscuits, and nuts.

Pharmaceuticals: Can handle pill packaging, tablets, and other small pharmaceutical products.

Consumer Goods: Perfect for packaging cosmetics, personal care items, and other similar products.

Why Choose the RC-Z1300?

Unmatched Speed and Efficiency: With speeds of up to 1300 pieces per minute, the RC-Z1300 helps businesses meet high-demand packaging needs.

Flexible and Versatile: Supports a variety of packaging shapes and materials, allowing businesses to easily switch between different products without needing additional machinery.

Precise Packaging: The advanced control system ensures that products are packaged with precision, reducing waste and improving packaging quality.

Energy-Efficient: Despite its high-speed performance, the machine is energy-efficient, helping to reduce long-term operational costs.

User-Friendly Operation: The intuitive interface allows for easy control and real-time adjustments, ensuring seamless integration into existing production lines.

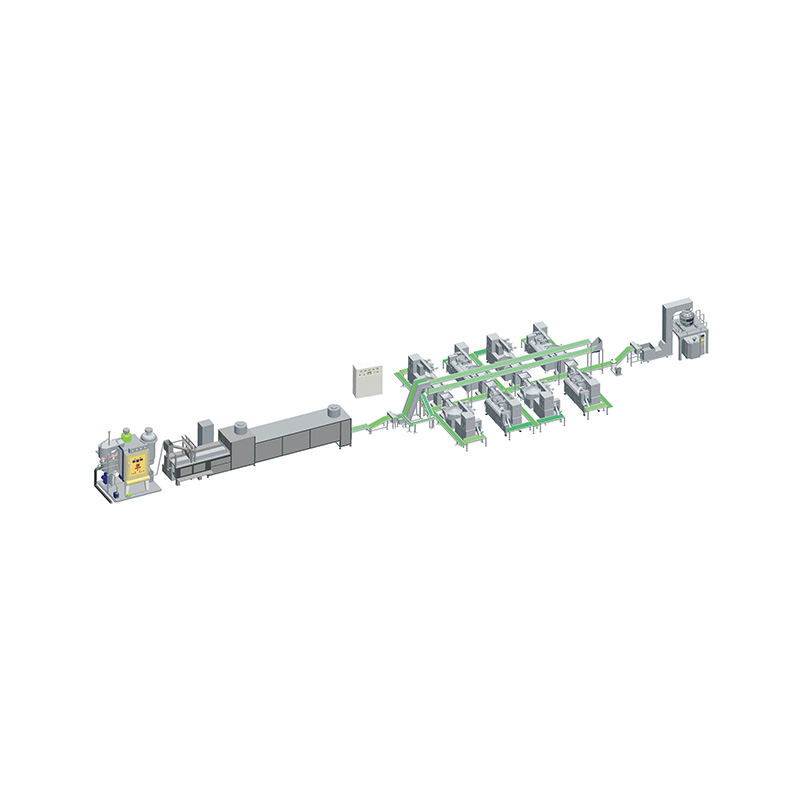

Zhejiang Rongchuang Intelligent Technology Co., Ltd. is a professional customized and automated food machinery manufacturer integrating R&D, manufacturing, sales, customer service, equipment import and export, and provides a full set of automation solutions for food machinery and turnkey intelligent technology projects. We supply RC-Z1300 High speed fully automatic multifunctional pillow package machine manufacturing and custom RC-Z1300 High speed fully automatic multifunctional pillow package machine exports.

The company's core team has 25 years of professional technical experience in the food machinery automation industry. It has successfully established several machinery and equipment factories in Shanghai, Guangdong, Fujian, and Zhejiang, with a total investment of approximately RMB 218 million.

The Rongchuang brand mainly produces a series of intelligent equipment such as pillow packaging machines, bag packaging machines, vertical packaging machines, double and single twist packaging machines, and a full set of solutions for conveying automation production lines.

With 25 years of industry technical experience and continuous exploration and progress, Rongchuang people insist on market and product innovation as the guide, and introduce advanced packaging equipment and technology, processing centers and testing instruments in Europe and the United States. The company adheres to the management model of 5s management, standardization, standardization, and intensiveness. "Rongchuang" is a win-win situation, and dares to create people first. Rongchuang people adhere to the spirit of integrity, responsibility, innovation and dedication, and take improving production efficiency, reducing production costs and enhancing corporate competitiveness as their mission. They continue to provide high-speed and efficient automated production intelligent equipment as well as a complete after-sales service system and technical support for the development of many food companies.

-

Running a twist packaging machine might seem straightforward at first glance: load the product, wrap it, twist, and move on. But any operator knows that material waste can sneak in at almost every ste...

READ MORE -

The flow pack machine has become a popular solution for packaging these types of products due to its ability to maintain product integrity while speeding up the packaging process. Flow pack machines a...

READ MORE -

A Twist Packaging Machine is a piece of equipment used to wrap individual products by enclosing them in a sheet of film or paper and then securing both ends with a simple twist. This type of wrapping ...

READ MORE -

A Chocolate Packaging Machine with adjustable speed settings plays an important role in modern confectionery production. This type of packaging equipment is designed to handle chocolate bars efficient...

READ MORE -

Chocolate Packaging Machine plays a pivotal role in modern confectionery production, transforming the way chocolates are packaged and presented. As market demand and competition increase, manufacturer...

READ MORE

English

English