The Fully Automatic Intelligent Vertical Mixer WZ-J50-A is a versatile and efficient machine designed for mixing and forming various food and confectionery materials. This mixer is particularly suited for handling sandy and gelatinous milk candies, nougat, snowflake pastries, and other types of confectionery and food ingredients. The mixer’s dimensions are 1370*900*1800 mm (length*width*height), making it compact yet powerful for industrial use.

-

Description

The WZ-J50-A Fully Automatic Intelligent Vertical Mixer is a cutting-edge machine built for high-efficiency blending and forming of a wide range of food and confectionery ingredients. Engineered to meet the demands of large-scale production, this versatile mixer is ideal for processing products such as milk candies, nougat, snowflake pastries, and various food seasonings. It streamlines the production process, offering unmatched precision and consistency in mixing.

Key Features:

1. Advanced Intelligent Control System

Color Touchscreen & PLC: The WZ-J50-A features a user-friendly interface with a color touchscreen and Programmable Logic Controller (PLC) for intuitive operation. This ensures precise control over the mixing process, allowing for quick adjustments to optimize production.

Efficient Operation: The intelligent control system simplifies operations, reducing the learning curve for operators while enhancing overall productivity.

2. Variable Frequency Drive (VFD)

Stepless Speed Control: With the integrated VFD, the mixer provides continuous and precise speed adjustments. Operators can customize the speed based on the recipe and ingredient requirements, ensuring the perfect blend every time.

Versatility in Handling: The VFD system accommodates a wide variety of ingredients, from soft to dense materials, offering exceptional flexibility.

3. Automatic Lifting Function

Ease of Operation: The automatic lifting mechanism simplifies material loading and unloading, reducing manual intervention. This innovation minimizes operator strain and accelerates the production cycle.

Labor Cost Reduction: By reducing the need for manual handling, the automatic lifting system significantly cuts labor costs while enhancing efficiency.

4. Silent, Reliable Synchronous Belt Transmission

Noise Reduction: The advanced synchronous belt design ensures quieter operation, contributing to a more comfortable and safer working environment.

Prevention of Oil Leakage & Slippage: The system prevents oil leakage and belt slippage, improving the reliability and longevity of the equipment.

5. Efficient Mixing with Multi-Paddle Design

Enhanced Mixing Speed: The WZ-J50-A's multi-paddle design optimizes the aeration and uniformity of the ingredients, especially for items like milk candies that require delicate mixing.

Consistent Results: The mixer guarantees consistent product quality by ensuring thorough and even blending, leading to higher product standards.

6. Safety & Monitoring Features

Alarm Lights: The WZ-J50-A is equipped with clearly visible alarm lights, indicating operational status and ensuring safety. This feature helps operators monitor the machine's performance and identify any issues quickly.

Real-Time Status Updates: Operators are kept informed about the machine's current cycle stage (standby, production, or completion) through these status indicators.

Additional Benefits:

1. Large 50KG Capacity

High Production Output: The WZ-J50-A is designed for large-scale operations, with a 50KG capacity, reducing the need for frequent batch processing and improving overall production efficiency.

2. Durable Stainless Steel Construction

Hygienic & Food-Safe: Made from high-quality stainless steel, the mixer complies with food safety standards. It is easy to clean, ensuring that hygiene is maintained during production.

Long-Lasting Durability: The stainless steel exterior ensures that the machine is resistant to wear and tear, providing longevity and low maintenance costs.

3. Convenient Transport Trolley

Easy Integration: The mixer comes with a transport trolley that allows for smooth integration into existing production lines, improving workflow and reducing material handling time.

4. Optional Automatic Scraper

Automated Discharge: The optional automatic scraper speeds up material discharge, minimizing downtime and further enhancing production efficiency.

Ideal Applications:

Candy & Confectionery Production: Perfect for mixing a wide variety of confectionery products such as milk candies, nougat, and snowflake pastries.

Food Processing: Ideal for processing food ingredients, spices, and seasonings, ensuring even mixing and high-quality output.

Large-Scale Manufacturing: The high capacity and automated functions make this mixer perfect for large-scale food production environments where efficiency is crucial.

-

Parameter

Capacity 50-100KG/h Total power 10KW Voltage 380V Noise <70 Chanting Weights 1150kg Machine dimensions: L1370×W900×H1800mm

Zhejiang Rongchuang Intelligent Technology Co., Ltd. is a professional customized and automated food machinery manufacturer integrating R&D, manufacturing, sales, customer service, equipment import and export, and provides a full set of automation solutions for food machinery and turnkey intelligent technology projects. We supply WZ-J50-A Fully Automatic Intelligent Vertical Mixer manufacturing and custom WZ-J50-A Fully Automatic Intelligent Vertical Mixer exports.

The company's core team has 25 years of professional technical experience in the food machinery automation industry. It has successfully established several machinery and equipment factories in Shanghai, Guangdong, Fujian, and Zhejiang, with a total investment of approximately RMB 218 million.

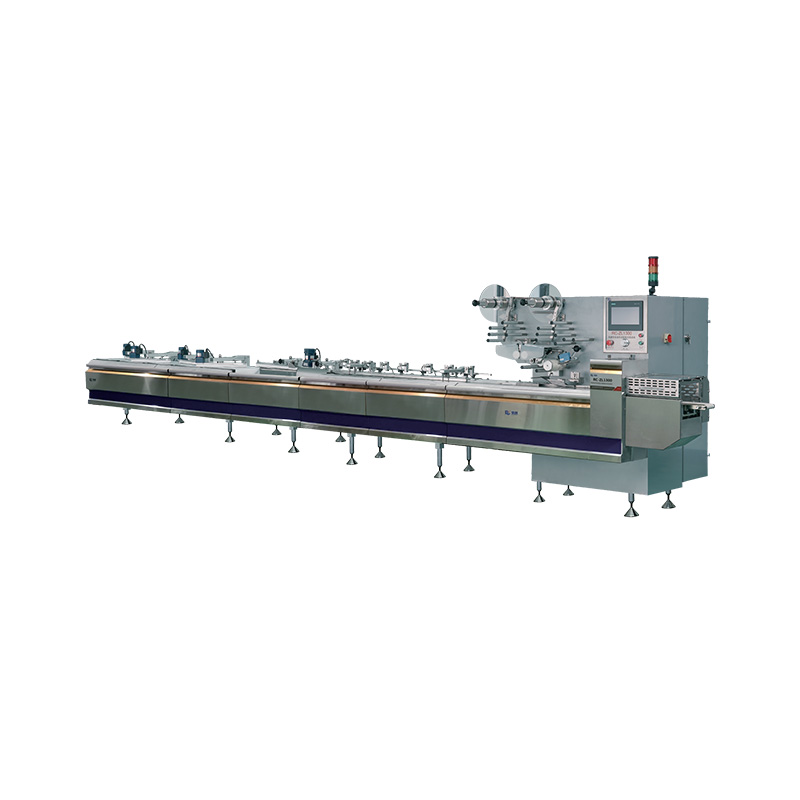

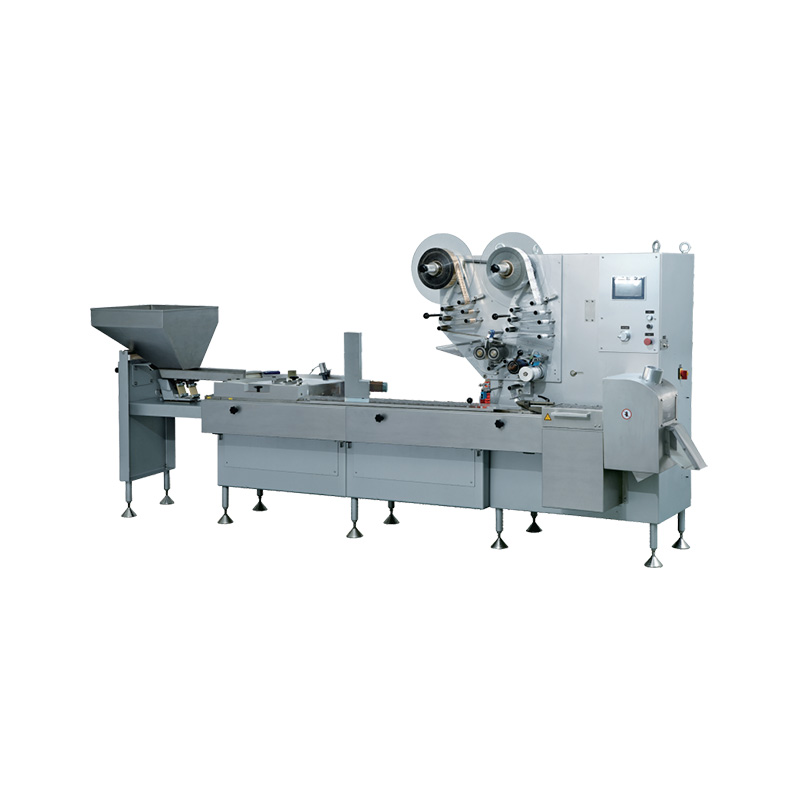

The Rongchuang brand mainly produces a series of intelligent equipment such as pillow packaging machines, bag packaging machines, vertical packaging machines, double and single twist packaging machines, and a full set of solutions for conveying automation production lines.

With 25 years of industry technical experience and continuous exploration and progress, Rongchuang people insist on market and product innovation as the guide, and introduce advanced packaging equipment and technology, processing centers and testing instruments in Europe and the United States. The company adheres to the management model of 5s management, standardization, standardization, and intensiveness. "Rongchuang" is a win-win situation, and dares to create people first. Rongchuang people adhere to the spirit of integrity, responsibility, innovation and dedication, and take improving production efficiency, reducing production costs and enhancing corporate competitiveness as their mission. They continue to provide high-speed and efficient automated production intelligent equipment as well as a complete after-sales service system and technical support for the development of many food companies.

-

In today’s manufacturing environment, efficiency and reliability are key factors that drive success. A vertical packaging machine factory has recently implemented a series of advanced automation techn...

READ MORE -

In the modern industrial world, automation plays a pivotal role in streamlining operations and improving overall efficiency. One significant advancement in automation is the fully automatic conveyor s...

READ MORE -

In recent years, the packaging industry has been undergoing rapid transformation. With the rise of global e-commerce, food delivery services, and retail distribution, the demand for efficient and reli...

READ MORE -

Running a twist packaging machine might seem straightforward at first glance: load the product, wrap it, twist, and move on. But any operator knows that material waste can sneak in at almost every ste...

READ MORE -

The flow pack machine has become a popular solution for packaging these types of products due to its ability to maintain product integrity while speeding up the packaging process. Flow pack machines a...

READ MORE

English

English