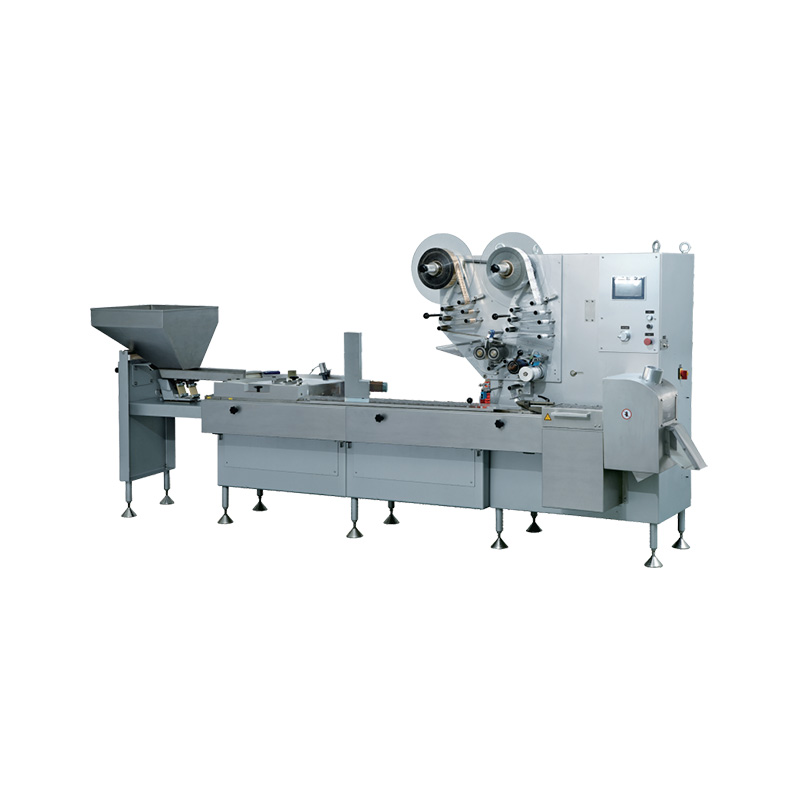

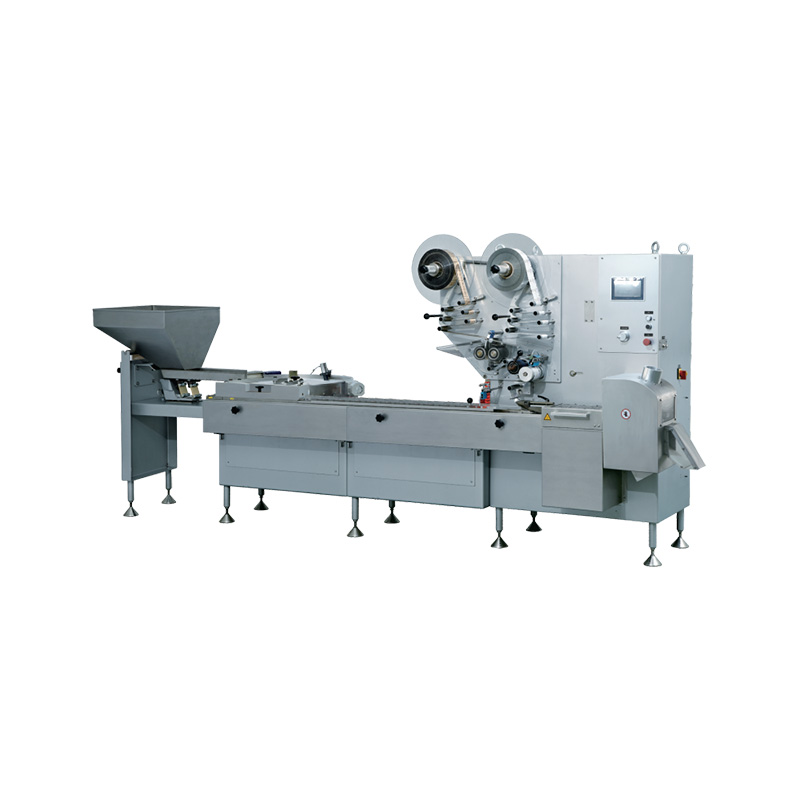

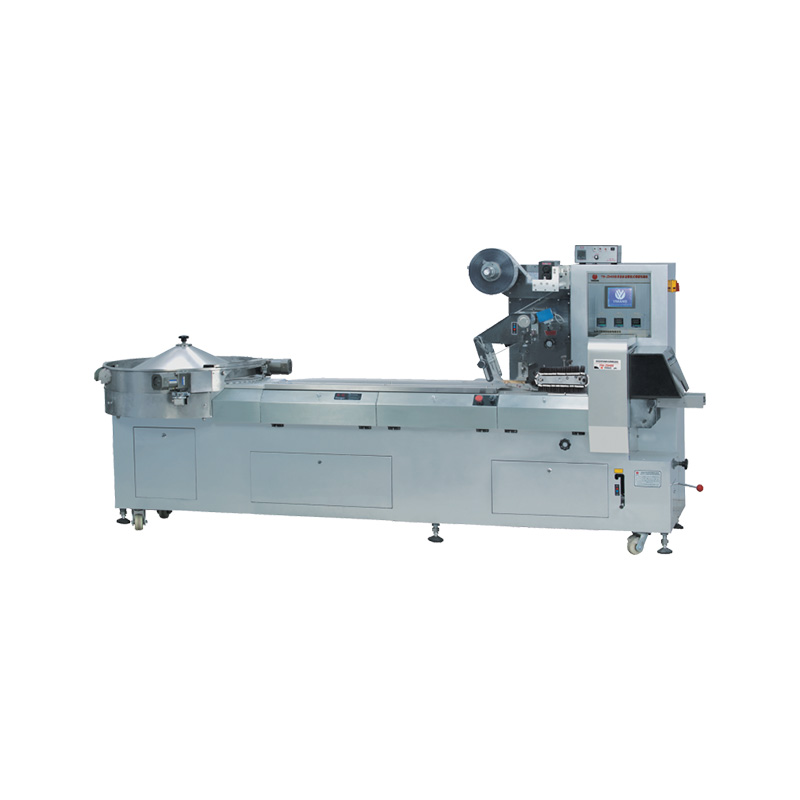

The Fully Automatic Multifunctional Lollipop Pillow Packaging Machine RC-ZB500 is designed to offer high-speed, efficient packaging for lollipops and other solid, regular-shaped items. This advanced packaging machine is capable of reaching speeds of up to 500 pieces per minute, ensuring a rapid and continuous packaging process. Equipped with a full servo industrial touch screen control system, the machine automates several steps, including film feeding, material loading, supplementary feeding, and continuous bag cutting.

-

Description

-

Parameter

Model model: RC-ZB500 Packaging speed: 50-500pcs/min Packaging size: 80-170mm Shape of packages: Round sheet, sphere, oval, waist round, cylindrical, etc. Total power: 6.5kw Outside dimensions: 3800*1200*1700mm Total weight: 1250kg Power supply: 380v 50Hz Packaging materials: OPP, CPP, PET aluminium-plated film, aluminium-plastic film, paper-plastic, paper-adhesive and other single-layer and multi-layer heat-sealable materials. Key Advantages of Using the RC-ZB500 in Modern Production Lines

Maximizing Operational Efficiency

In today's fast-paced production environment, businesses need machines that can keep up with high demands. The RC-ZB500 delivers on this front by offering an automated, high-speed packaging solution. With packaging speeds of up to 500 pieces per minute, this machine streamlines the entire packaging process, allowing for rapid output without sacrificing quality. By automating critical processes, such as film feeding, material loading, and bag cutting, it significantly reduces labor requirements, freeing up resources for other aspects of production.

Enhanced Scalability for Growing Businesses

As production volumes grow, businesses need packaging systems that can scale seamlessly. The RC-ZB500 allows for rapid scaling of operations while maintaining the same level of precision and efficiency. With its adjustable packaging speeds and customizable settings, the machine ensures that businesses can continue to meet increasing demand without bottlenecks or downtime.

Reduction in Manual Labor and Human Error

By automating various stages of the packaging process, the RC-ZB500 reduces reliance on manual labor, which is not only more cost-effective but also significantly reduces the risk of human error. The machine is equipped with a servo-driven system, which ensures that the machine operates with minimal intervention, thus enhancing consistency and overall packaging quality.

Improved Product Consistency

One of the key benefits of automation is the consistency it provides. The RC-ZB500's servo-controlled system ensures that every package is sealed correctly and uniformly, whether you're packaging lollipops, candies, or other solid, regular-shaped items. The precise control over film tension, seal pressure, and cut length guarantees that your products are packaged securely and attractively, which is essential for brand consistency.

Maximum Packaging Speed: Up to 500 Pieces Per Minute

The RC-ZB500 is built for speed, capable of packaging up to 500 pieces per minute, making it one of the fastest machines in its class. This rapid speed allows companies to keep pace with high-volume production demands while maintaining the flexibility to handle varying product types and packaging requirements. Whether you are dealing with large or small batches, the RC-ZB500 ensures that your production line remains productive throughout the day.

Optimized Workflow: The high-speed operation ensures that the packaging process is efficient, reducing downtime and increasing throughput.

Faster Time-to-Market: By speeding up packaging, businesses can shorten the time it takes to get products to market, helping them remain competitive in an ever-evolving market.

How High-Speed Operation Enhances Production Output

The high-speed capabilities of the RC-ZB500 directly translate into enhanced production output. Faster packaging speeds mean that businesses can process more units in a shorter amount of time, significantly improving overall operational efficiency. This translates into better profit margins and increased productivity.

Less Downtime: The RC-ZB500 operates continuously, with minimal interruptions between production cycles. This ensures that your packaging line remains active for longer periods, maximizing productivity.

Optimal Speed and Quality Balance: Unlike traditional packaging methods, where speed may compromise quality, the RC-ZB500 ensures that both speed and precision are maintained, ensuring consistent, high-quality packaging.

Maintaining Accuracy at High Speeds to Ensure Consistent Quality

Maintaining accuracy at high speeds can be challenging, but the RC-ZB500 excels in this area. The servo motor control and advanced PLC technology ensure that every product is packaged with consistent accuracy even at maximum speeds. The automated system adjusts film feeding, material loading, and bag cutting based on real-time feedback, allowing for precise control over each package.

Servo Motor Technology: The use of servo motors allows the machine to maintain precision even under high-speed operation, ensuring that each package is uniformly sealed and filled.

Continuous Bag Cutting: The RC-ZB500's continuous bag cutting system ensures that the bags are cut with precision, minimizing waste and providing clean seals for every package.

Automated Film Feeding: The automated film feeding system adjusts to varying film materials, reducing errors and ensuring that the film is applied correctly, consistently, and without any wrinkles.

Zhejiang Rongchuang Intelligent Technology Co., Ltd. is a professional customized and automated food machinery manufacturer integrating R&D, manufacturing, sales, customer service, equipment import and export, and provides a full set of automation solutions for food machinery and turnkey intelligent technology projects. We supply RC-ZB500 Fully Automatic Multifunctional Lollipop Pillow Packaging Machine manufacturing and custom RC-ZB500 Fully Automatic Multifunctional Lollipop Pillow Packaging Machine exports.

The company's core team has 25 years of professional technical experience in the food machinery automation industry. It has successfully established several machinery and equipment factories in Shanghai, Guangdong, Fujian, and Zhejiang, with a total investment of approximately RMB 218 million.

The Rongchuang brand mainly produces a series of intelligent equipment such as pillow packaging machines, bag packaging machines, vertical packaging machines, double and single twist packaging machines, and a full set of solutions for conveying automation production lines.

With 25 years of industry technical experience and continuous exploration and progress, Rongchuang people insist on market and product innovation as the guide, and introduce advanced packaging equipment and technology, processing centers and testing instruments in Europe and the United States. The company adheres to the management model of 5s management, standardization, standardization, and intensiveness. "Rongchuang" is a win-win situation, and dares to create people first. Rongchuang people adhere to the spirit of integrity, responsibility, innovation and dedication, and take improving production efficiency, reducing production costs and enhancing corporate competitiveness as their mission. They continue to provide high-speed and efficient automated production intelligent equipment as well as a complete after-sales service system and technical support for the development of many food companies.

-

Running a twist packaging machine might seem straightforward at first glance: load the product, wrap it, twist, and move on. But any operator knows that material waste can sneak in at almost every ste...

READ MORE -

The flow pack machine has become a popular solution for packaging these types of products due to its ability to maintain product integrity while speeding up the packaging process. Flow pack machines a...

READ MORE -

A Twist Packaging Machine is a piece of equipment used to wrap individual products by enclosing them in a sheet of film or paper and then securing both ends with a simple twist. This type of wrapping ...

READ MORE -

A Chocolate Packaging Machine with adjustable speed settings plays an important role in modern confectionery production. This type of packaging equipment is designed to handle chocolate bars efficient...

READ MORE -

Chocolate Packaging Machine plays a pivotal role in modern confectionery production, transforming the way chocolates are packaged and presented. As market demand and competition increase, manufacturer...

READ MORE

English

English