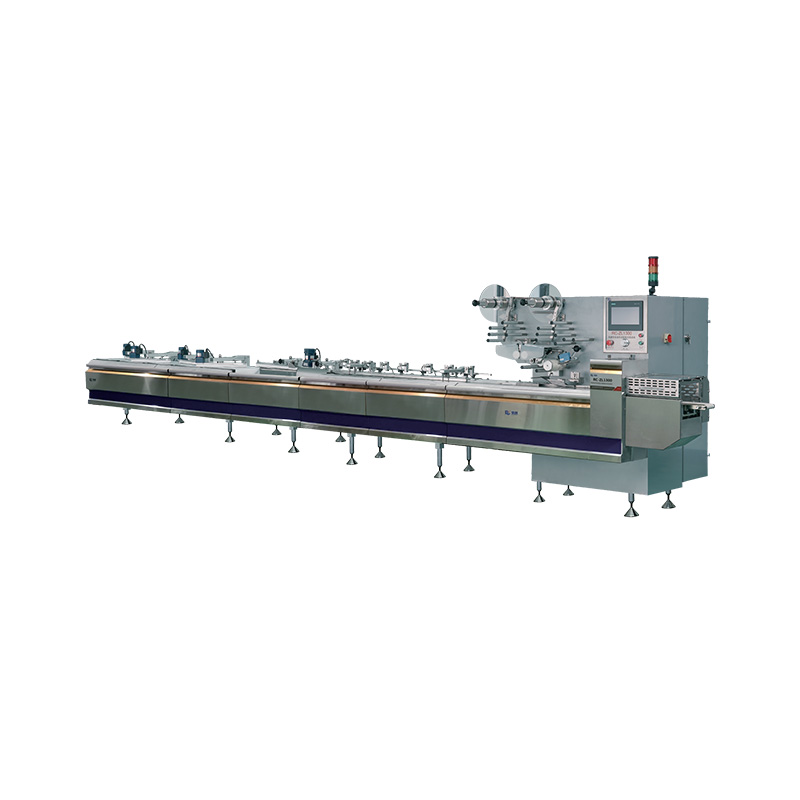

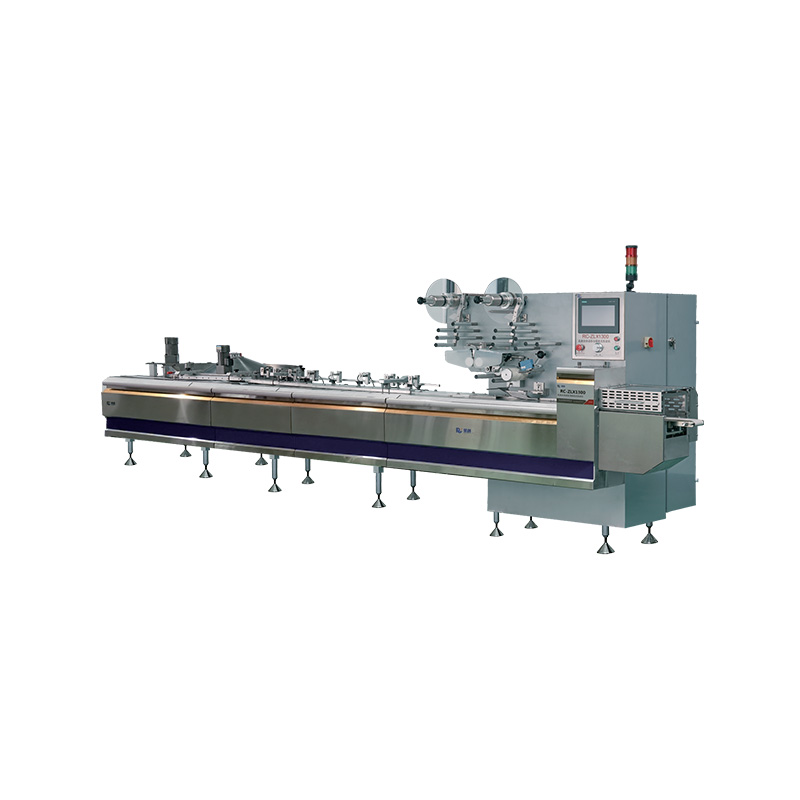

| Model model: |

RC-Z1200 |

| Packaging speed: |

50-1200pcs/min |

| Packaging size: |

50-60mm |

| Shape of packages: |

Segmented, spherical, oval, waisted, cylindrical, etc. |

| Total power: |

4.5kw |

| Outside dimensions: |

2350*1280*1580mm |

| Total weight: |

1400kg |

| Power supply: |

220v 50Hz |

| Packaging materials: |

OPP, CPP, PET Aluminium-plated film, aluminium-plastic film, paper-plastic, paper-adhesive and other single-layer and multi-layer heat-sealable materials. |

The RC-Z1200 Fully Automatic Multifunctional Pillow Packaging Machine is designed to help businesses optimize their packaging processes and improve overall efficiency. With its advanced features, the RC-Z1200 offers several key benefits that make it an excellent investment for businesses in a variety of industries.

Boosting Productivity: High-Speed Operation with Minimal Downtime

One of the standout features of the RC-Z1200 is its high-speed operation. Capable of packaging up to 1200 pieces per minute, this machine ensures that your production line operates at maximum capacity. With minimal downtime between cycles, it efficiently handles high volumes, increasing overall output while keeping production costs down. This high-speed capability makes the RC-Z1200 an invaluable tool for businesses that require fast, continuous packaging processes.

Quick Setup: The machine's advanced design allows for swift adjustments to packaging speeds and product sizes, reducing setup times.

Reduced Idle Time: With automated feeding and cutting systems, the RC-Z1200 minimizes downtime, keeping your production line running smoothly.

Cost Savings: Reduced Labor Costs Through Automation

The RC-Z1200 is a fully automated system, meaning less reliance on manual labor and fewer operational costs. By automating key packaging functions like material feeding, sealing, and bag cutting, the machine reduces the need for human operators. This leads to substantial cost savings over time, as labor expenses decrease and the need for human intervention is minimized.

Less Labor-Intensive: With its fully automated nature, the RC-Z1200 reduces the number of operators required to manage the packaging process.

Enhanced Efficiency: Labor costs are further reduced by eliminating manual errors, which often lead to rework and wasted materials.

Product Consistency: Ensuring Uniform and Secure Packaging

Consistency in product packaging is critical for both customer satisfaction and brand identity. The RC-Z1200 ensures that every product is packaged uniformly, with the same level of sealing and film quality. Whether you're packaging lollipops, candies, or other small items, the machine guarantees secure packaging that keeps products fresh and intact.

Precise Sealing: The servo-controlled system offers precise sealing, ensuring every package is tightly sealed and ready for shipment.

High-Quality Output: The machine's consistent performance ensures uniformity in packaging quality, boosting customer satisfaction.

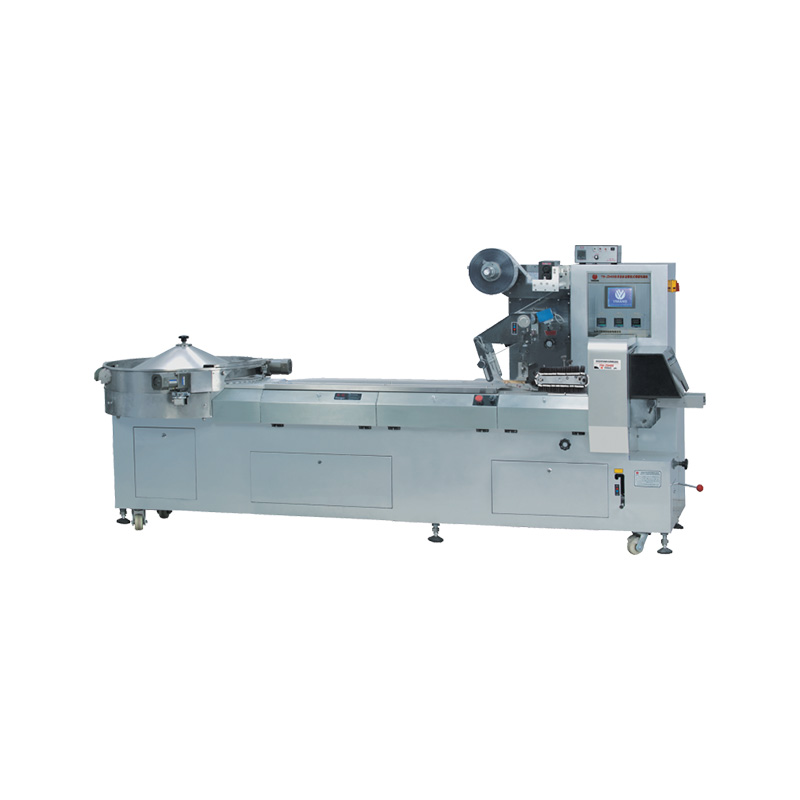

Flexibility for Various Products: Adaptable to Different Shapes and Sizes

The RC-Z1200 is designed with flexibility in mind. It can easily handle a wide range of product sizes and shapes, from small candies to larger confectionery items. The adjustable packaging size and customizable settings make it easy to adapt the machine to different products, allowing you to switch between product types without downtime or complex adjustments.

Versatile Packaging: Capable of packaging products ranging from small round lollipops to cylindrical chocolates, the RC-Z1200 can accommodate diverse packaging needs.

Quick Adjustments: Easily modify packaging size, film type, and sealing settings for different product runs, ensuring smooth transitions between packaging different items.

Energy Efficiency: Reduced Power Consumption for Long-Term Savings

The RC-Z1200 is built with energy efficiency in mind. Featuring low power consumption, the machine minimizes energy use while still delivering high-speed, high-volume packaging. Over time, this can result in significant cost savings on your electricity bills, making the RC-Z1200 a sustainable choice for businesses aiming to reduce their environmental footprint and operating costs.

Energy-Saving Technology: Advanced power management ensures that the machine operates efficiently, using only the energy necessary to maintain optimal performance.

Sustainable Operation: The machine's energy-efficient design contributes to a greener manufacturing process, which can enhance your company’s sustainability credentials.

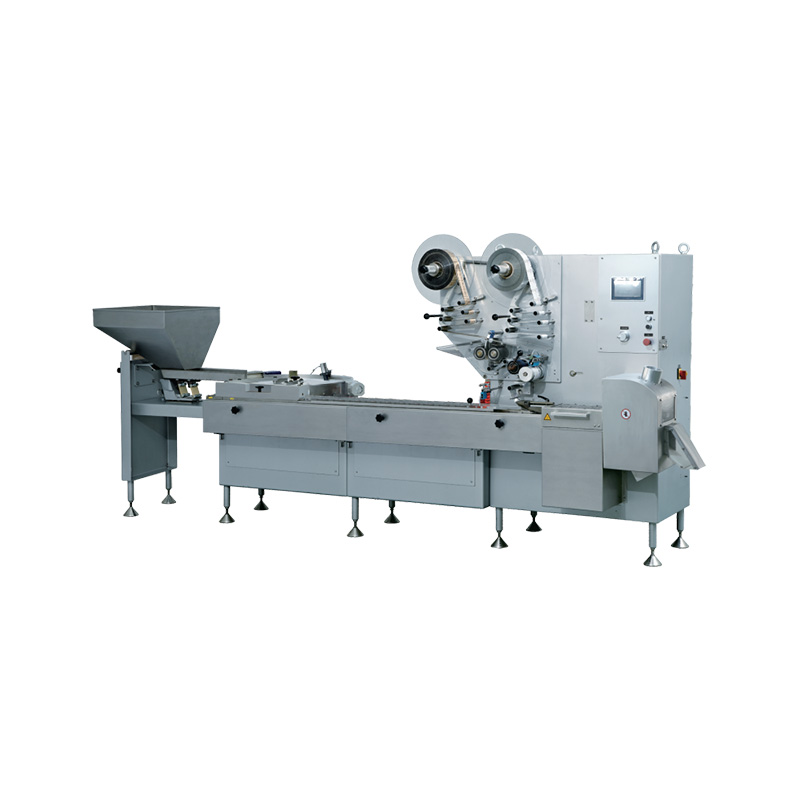

Applications of the RC-Z1200 Pillow Packaging Machine

The RC-Z1200 is highly versatile and adaptable, capable of packaging a wide variety of products across different industries. Whether you're in the food, confectionery, or pharmaceutical sectors, the RC-Z1200 provides an efficient and reliable solution for your packaging needs.

Packaging of Confectioneries: Ideal for Lollipops, Candies, and Chocolates

The RC-Z1200 is perfectly suited for the confectionery industry, where speed, precision, and high-quality packaging are essential. This machine is ideal for packaging lollipops, candies, chocolates, and other sweet treats. Its advanced features ensure that even delicate confectioneries are securely packaged, preserving their shape, texture, and freshness.

Perfect for Delicate Items: The RC-Z1200 offers soft handling of fragile products, ensuring that candies and chocolates remain intact during the packaging process.

Secure and Attractive Packaging: The machine ensures that every confectionery is sealed securely and attractively, creating a visually appealing final product.

Food Industry Applications: Packaging Snacks, Biscuits, and More

The RC-Z1200 is also well-suited for packaging a variety of other food products, such as biscuits, snacks, baked goods, and frozen foods. Its ability to handle different product sizes and shapes, coupled with its high-speed operation, makes it an excellent choice for food manufacturers looking to optimize their packaging processes.

Wide Range of Applications: Ideal for snacks, granola bars, biscuits, and more, the RC-Z1200 offers flexibility for various food types.

Quality Sealing for Freshness: Ensures products are sealed tightly, maintaining freshness and preventing contamination.

Pharmaceutical and Non-Food Products: Versatile Packaging for Various Industries

The versatility of the RC-Z1200 extends beyond food packaging, making it suitable for pharmaceutical products and other non-food items. Whether you’re packaging small tablets, capsules, or even industrial items, this machine ensures secure and efficient packaging.

Packaging for Pharmaceuticals: The machine can handle bottle caps, blister packs, and even non-food consumables such as small parts or components.

Versatile Packaging Solutions: It can be adapted for use in multiple industries, ensuring your products are securely and attractively packaged.

Customization: Tailoring the Machine for Different Industries and Products

One of the strongest selling points of the RC-Z1200 is its customizability. It can be tailored to fit the specific needs of your business, with options for adjusting packaging size, material, and sealing settings. This flexibility makes the RC-Z1200 a long-term investment for businesses with varied production lines.

Adaptable Settings: Easily adjust the machine to handle new products, sizes, and shapes, ensuring the packaging process remains streamlined and efficient.

Industry-Specific Solutions: Customizable features allow you to tailor the machine to meet the unique demands of your industry, whether it’s food, pharmaceutical, or manufacturing.

English

English