Vertical Packaging Machine Factory Introduces Advanced Automation Technology

In today’s manufacturing environment, efficiency and reliability are key factors that drive success. A vertical packaging machine factory has recently implemented a series of advanced automation technologies to enhance production processes and improve operational consistency. These updates reflect a broader trend in the manufacturing sector, where machinery is increasingly integrated with intelligent systems to streamline workflows.

The factory produces a range of vertical packaging machines suitable for industries such as food, pharmaceuticals, and daily chemicals. By incorporating automated functions, the factory has been able to reduce manual interventions, decrease downtime, and maintain a steady pace of production. Operators now have access to user-friendly interfaces, allowing them to monitor machine performance and adjust settings without interrupting production lines.

Automation Features in Vertical Packaging

Modern vertical packaging machines combine precision mechanics with digital control systems. These machines can handle different packaging materials, including films, foils, and laminates, and are designed to fill, seal, and label products efficiently. Automation plays a crucial role in synchronizing these functions, ensuring that each package meets consistent quality standards.

One notable feature of the upgraded machines is the integration of sensors and intelligent detection systems. These components help identify material inconsistencies, prevent misalignment, and reduce the likelihood of packaging errors. Additionally, automated weighing and dosing systems ensure that products are accurately portioned, supporting both cost management and product quality.

Supporting Versatility in Production

The vertical packaging machine factory emphasizes versatility in its product offerings. Machines can be configured to accommodate different package sizes, bag shapes, and filling types. This flexibility is particularly valuable for clients with diverse product lines or seasonal variations in demand. Automation allows these adjustments to be made quickly, reduces production interruptions, and increases overall efficiency.

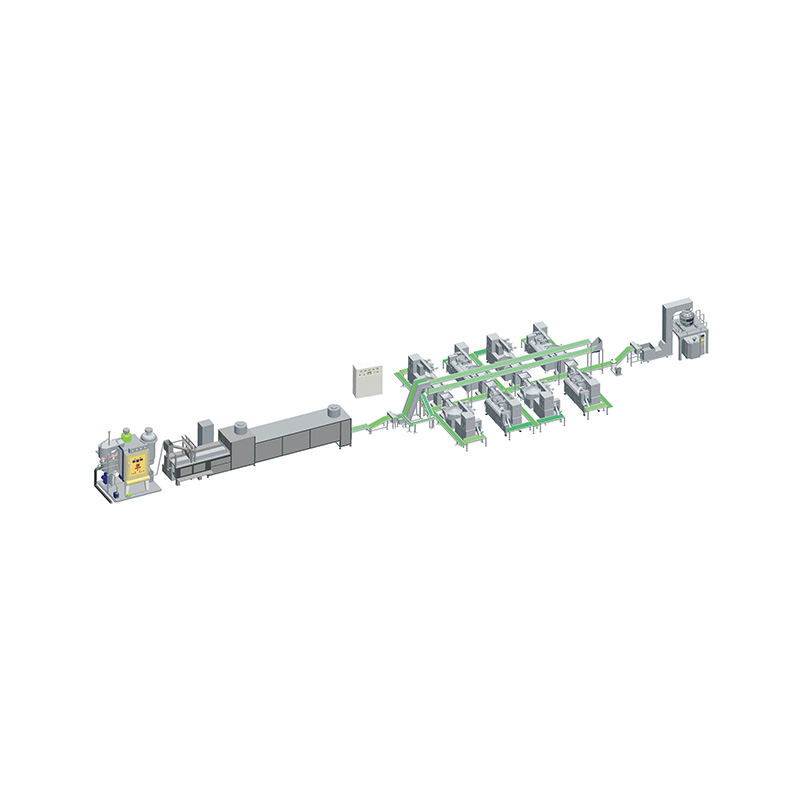

Moreover, the factory has worked to ensure that its machines are compatible with supplementary equipment, such as conveyors, labeling units, and inspection systems. This compatibility supports the creation of fully integrated production lines, where multiple processes are coordinated without the need for manual handling between stages.

Collaboration with Vertical Mixer Technology

In addition to packaging machines, the factory has explored synergies with vertical mixer technology. Vertical mixers are widely used in industries such as food processing, chemical production, and material handling, where precise mixing of powders, granules, or liquid-solid combinations is required. By integrating vertical mixers with automated packaging lines, manufacturers can achieve continuous, streamlined production from raw material preparation to final packaging.

This collaboration between packaging and mixing technologies allows for improved workflow efficiency. Materials can be mixed to a uniform consistency and immediately transferred to packaging machines, reducing waiting times and the risk of contamination. For businesses managing multiple product formulas, this combination offers a practical solution for maintaining both speed and product quality.

Benefits for Clients and Operators

The implementation of advanced automation technology in vertical packaging machines provides several benefits. For operators, automated systems reduce the physical effort required for routine tasks and provide a safer working environment. Machines can detect malfunctions, trigger alarms, and even pause operations when necessary, allowing staff to address issues promptly without causing significant production loss.

For clients, the consistency and reliability of automated machines help ensure that products meet expected standards. Accurate filling, sealing, and labeling processes support brand quality and reduce the chances of returns or complaints. Additionally, the flexibility offered by these systems enables manufacturers to respond more quickly to market changes and customer preferences.

Looking Forward

As manufacturing continues to evolve, automation is likely to play an increasingly central role in vertical packaging and material handling. The factory’s recent upgrades demonstrate a commitment to adopting technology that enhances production efficiency, operational reliability, and product consistency. By combining packaging and vertical mixer technologies, manufacturers can create integrated, adaptable production lines that meet the demands of a dynamic market environment.

With these advancements, the vertical packaging machine factory positions itself as a resource for clients seeking practical solutions for modern production challenges. The focus on automation does not replace human oversight but rather empowers operators to work more efficiently, supporting smoother workflows and higher quality outcomes.

English

English