Vertical Packaging Machine Factory Expands Production Capacity For Global Demand

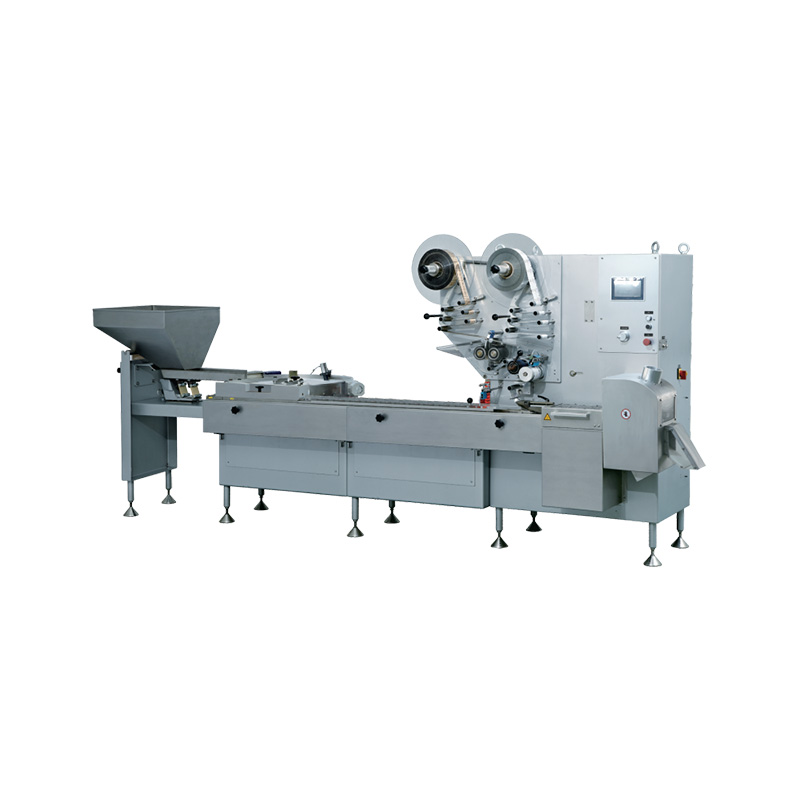

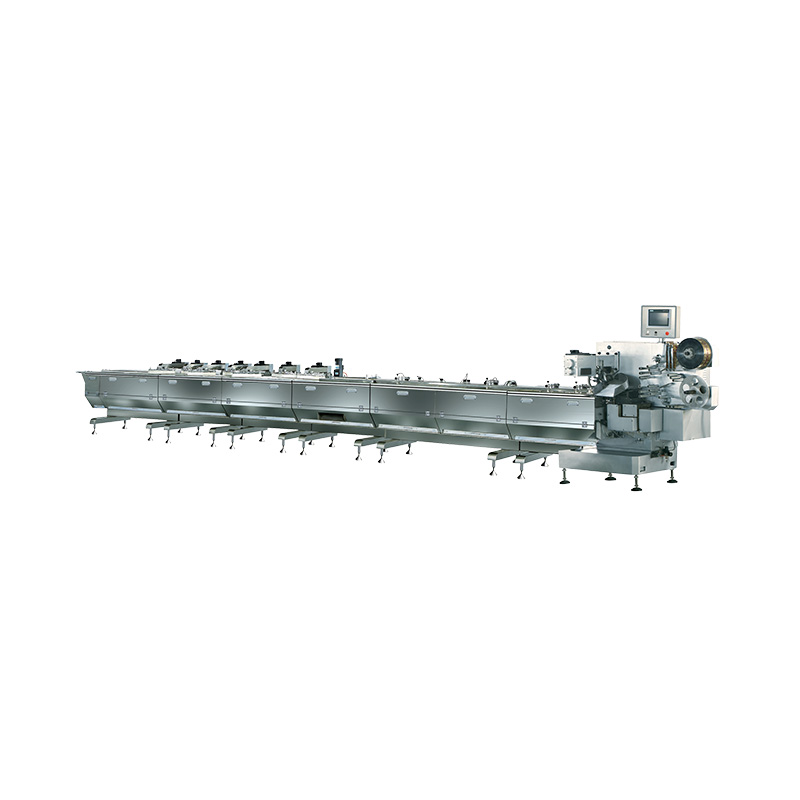

In recent years, the packaging industry has been undergoing rapid transformation. With the rise of global e-commerce, food delivery services, and retail distribution, the demand for efficient and reliable packaging equipment continues to grow steadily. A Vertical Packaging Machine Factory plays a central role in meeting this demand, providing flexible equipment solutions for various sectors including food, pharmaceuticals, agriculture, and consumer goods. To keep pace with increasing requirements, the factory has expanded its production capacity, focusing on technology upgrades and streamlined manufacturing processes.

Expansion of Production Facilities

The expansion is not just about adding more machines on the assembly line. It involves comprehensive improvements to the facility layout, supply chain management, and workforce development. By investing in larger workshops and modernized production equipment, the Vertical Packaging Machine Factory is now able to shorten advance times while maintaining consistent product quality. This adjustment also provides room for more product variations, allowing the factory to respond to diverse client specifications across international markets.

Integration of Automation and Efficiency

One of the key goals of the expansion is to integrate automation into the entire production cycle. From raw material processing to final assembly, automated systems reduce manual handling and improve precision. For customers, this translates into packaging machines that offer stable performance and lower maintenance requirements. Moreover, the introduction of automated monitoring systems allows the factory to detect potential production issues earlier, which helps ensure that each unit meets strict quality benchmarks before being shipped.

Collaboration with Vertical Mixer Factory

The packaging industry is not isolated from other machinery sectors. For example, many food and chemical processing companies require both mixing and packaging equipment to complete their production lines. A Vertical Mixer Factory often works in close connection with a Vertical Packaging Machine Factory to deliver integrated solutions. Mixers are essential for blending ingredients uniformly before they are packed, while vertical packaging machines handle sealing, portioning, and labeling. By aligning production schedules and design standards, these two types of factories can jointly serve clients who need comprehensive systems rather than stand-alone machines.

Product Diversification to Support Global Clients

As international demand increases, customization has become a central theme in the factory’s development strategy. Different regions have varying packaging standards, consumer preferences, and regulatory requirements. To address these factors, the Vertical Packaging Machine Factory has diversified its product range. Clients can choose equipment that supports various packaging materials, bag sizes, and sealing formats. Whether it is powder, granules, liquids, or ready-to-eat snacks, the factory now offers equipment solutions adapted to each application.

Sustainability in Packaging Machinery Manufacturing

Sustainability is an area that no modern manufacturer can overlook. The Vertical Packaging Machine Factory has introduced eco-conscious design concepts into its production. Machines are engineered to reduce energy consumption during operation while also being compatible with recyclable and biodegradable packaging films. Additionally, the factory is exploring ways to lessen material waste during machine testing, ensuring that environmental considerations are part of daily operations. These steps not only align with global sustainability goals but also support customers who are striving to meet their own environmental commitments.

Workforce Development and Training

Behind every successful expansion project is a team of skilled professionals. The factory has invested heavily in staff training, ensuring that workers are familiar with new technologies, safety practices, and international quality standards. Training sessions cover mechanical assembly, software operation, and troubleshooting, creating a workforce capable of supporting clients even after the sale is complete. The emphasis on people reflects the factory’s recognition that machinery development is as much about human expertise as it is about advanced equipment.

Future Outlook for Vertical Packaging Solutions

Looking ahead, the Vertical Packaging Machine Factory is positioned to play a significant role in shaping the next stage of packaging technology. Continued cooperation with related sectors, such as the Vertical Mixer Factory, will allow for more integrated production line solutions. At the same time, sustained investment in research and development is expected to bring forth innovations in packaging speed, flexibility, and sustainability. With its expanded capacity and broadened scope, the factory is better prepared to respond to evolving customer requirements across global markets.

The expansion of the Vertical Packaging Machine Factory reflects a proactive approach to changing market dynamics. By enlarging its production facilities, adopting automation, and working closely with related industries like the Vertical Mixer Factory, it has positioned itself to meet worldwide demand more effectively. Through diversification, sustainability efforts, and workforce training, the factory demonstrates that growth can be achieved while maintaining balance between efficiency, innovation, and environmental responsibility. This strategic direction ensures that the factory’s role in the global packaging supply chain will continue to strengthen in the years to come.

English

English