How a Pillow Packaging Machine Can Improve Production Efficiency?

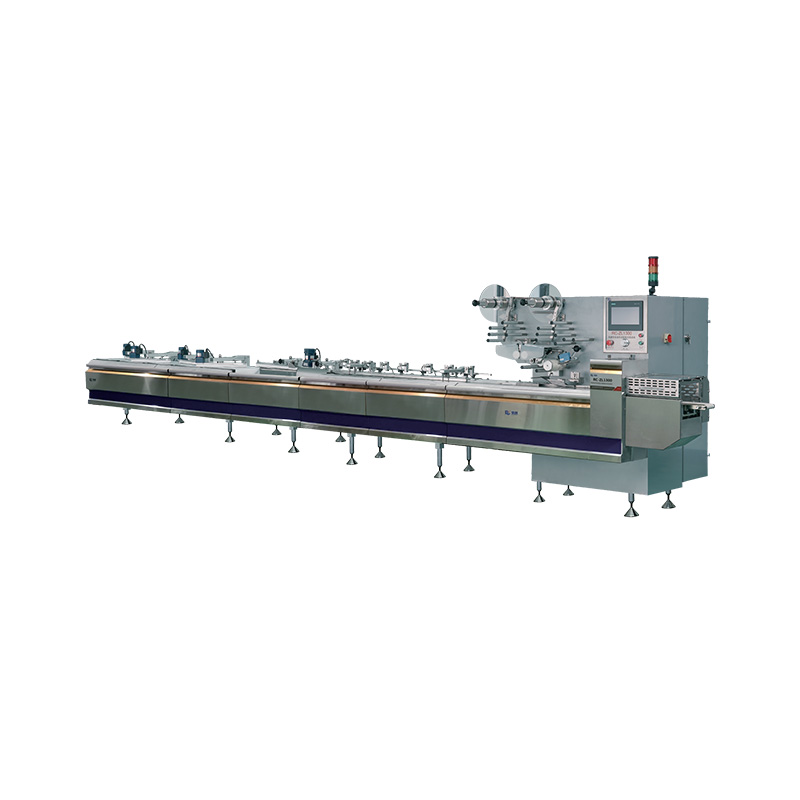

In today’s competitive manufacturing environment, efficiency is a key factor in determining success. As industries continue to look for ways to enhance productivity and reduce costs, a Pillow Packaging Machine has emerged as a valuable tool in achieving these goals. This automated solution for packaging offers numerous advantages that directly impact production efficiency. By streamlining the packaging process, a Pillow Packaging Machine can help manufacturers optimize their operations and meet market demands more effectively.

One of the main reasons a Pillow Packaging Machine improves production efficiency is its ability to automate the entire packaging process. Traditionally, packaging was a labor-intensive task, often requiring manual labor to wrap and seal products. This not only slowed down production but also introduced the potential for human error. By automating this process, a Packaging Machine eliminates the need for manual intervention, resulting in faster and more consistent packaging.

Automation results in a faster workflow, reducing the time spent on each product. As a result, manufacturers can package more items within a given time frame, significantly increasing overall production capacity.

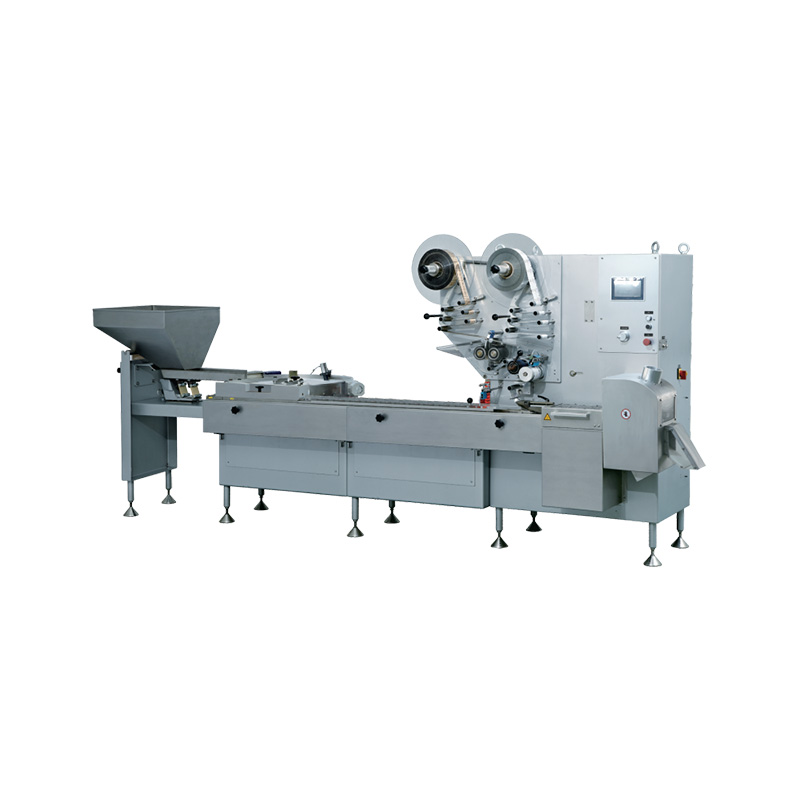

A Pillow Packaging Machine ensures consistent packaging quality, which plays a critical role in maintaining efficiency. In manual packaging processes, there can be variations in the way products are wrapped, resulting in uneven sealing and packaging defects. This not only results in wasted materials but can also result in products being improperly sealed, potentially compromising their safety and shelf life.

With a Pillow Packaging Machine, every package is wrapped uniformly and securely. The machine is designed to apply precise pressure and temperature to ensure that each product is sealed effectively. This consistency reduces the need for rework or repairs, saving time and resources. Additionally, high-quality packaging helps reduce the chances of product damage during storage or transit, further enhancing operational efficiency.

Labor costs are a significant factor in the overall expenses of a manufacturing operation. A Pillow Packaging Machine can help reduce these costs by automating the packaging process. Instead of relying on a team of workers to wrap products manually, the machine takes over this task, requiring only minimal human intervention for setup and maintenance.

By reducing the need for manual labor, manufacturers can reallocate their workforce to other areas of production where human oversight is more necessary. This not only helps save on wages but also allows for better utilization of resources, increasing the overall efficiency of the production line.

Packaging materials are an essential part of the production process, and waste can quickly accumulate if not properly managed. A Pillow Packaging Machine helps reduce material waste by accurately dispensing the right amount of packaging material for each product. Traditional packaging methods often result in excess material being used, resulting in higher costs and more waste.

The precise operation of the Packaging Machine ensures that only the necessary amount of material is used for each package. This reduces waste and helps manufacturers optimize their material usage, which in turn contributes to overall cost savings and increased efficiency. Additionally, the machine’s ability to handle different sizes and types of packaging materials further improves its versatility and efficiency in production.

The Pillow Packaging Machine plays a key role in streamlining the entire production workflow. In traditional packaging methods, the packaging process is often a bottleneck, slowing down the overall flow of production. By automating packaging, the Packaging Machine eliminates this bottleneck, allowing for a more seamless transition between production stages.

Once the products are produced, they can be quickly transferred to the Pillow Packaging Machine for wrapping and sealing. This efficiency reduces delays between production and packaging, helping manufacturers meet tight deadlines and optimize their production schedules.

A major advantage of the Pillow Packaging Machine is its flexibility. These machines are capable of packaging a wide range of product sizes and shapes, making them suitable for various industries. Whether the products are small, large, or irregularly shaped, the Pillow Packaging Machine can be easily adjusted to accommodate different packaging requirements.

English

English