How to Choose the Right Fully Automatic Conveyor for Your Production Needs

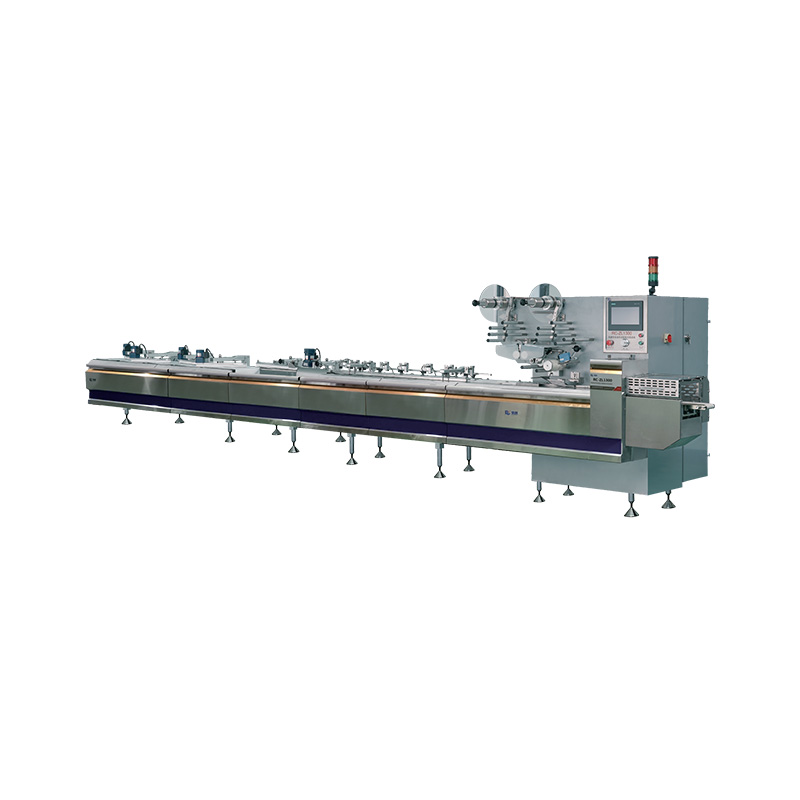

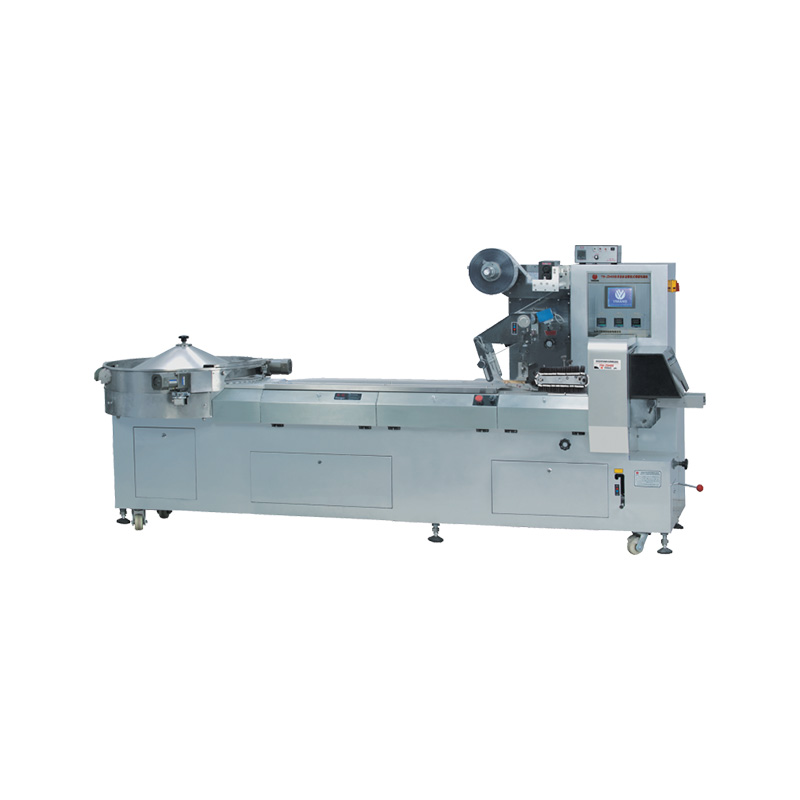

Choosing the right Fully Automatic Conveyor for your production line is an important decision that can affect the efficiency and smooth operation of your business. These systems are designed to automate the movement of products, reducing manual labor and helping maintain a steady workflow. However, with many options available, it’s helpful to know what to consider before making a purchase.

It’s important to understand what type of materials you will be moving with the Fully Automatic Conveyor. Different products require different handling methods. For example, small, lightweight items like packaged snacks need a different conveyor belt compared to heavy industrial parts or bulky boxes. Knowing the size, weight, and shape of your products will help you select a conveyor system that can support them safely and efficiently.

Next, think about the speed and volume of your production. How many items do you need to move in a given time? If your production line runs at a high pace, you will want a Fully Automatic Conveyor capable of keeping up without causing delays. On the other hand, if your operation is steady but slower, a system with adjustable speed settings can be more practical. Matching the conveyor speed with your production demand helps maintain smooth operation.

Space availability is another key factor. Production areas can vary widely in size and layout, so it’s important to measure the available floor and wall space where the Fully Automatic Conveyor will be installed. Some conveyors are designed to be compact or can be arranged vertically or around corners to save space. Choosing a conveyor system that fits your workspace well ensures easy installation and prevents disruptions to other equipment.

The control system of the Fully Automatic Conveyor also deserves attention. Modern conveyors often come with programmable settings that allow operators to adjust speed, start and stop times, and direction. Having user-friendly controls can make daily operations easier and safer. Also, if your production line includes other automated machines, selecting a conveyor that can integrate smoothly with existing systems can improve overall efficiency.

Consider the durability and material of the Fully Automatic Conveyor. Since production lines can be busy environments, the conveyor needs to withstand continuous use without frequent breakdowns. Materials like stainless steel or coated metals often resist wear and corrosion better, especially in environments where moisture or dust is present. Choosing a sturdy conveyor system can save money on repairs and reduce downtime.

Maintenance is another important aspect to think about. A conveyor that is easy to clean and maintain will help keep your production line running longer without interruption. Look for models where parts can be quickly accessed or replaced, and check whether regular maintenance is straightforward. This can reduce the time your team spends troubleshooting or fixing the system.

When considering a Fully Automatic Conveyor for your operations, prioritizing safety features is paramount. Integral to these systems are emergency stop buttons, protective guards, and sensors designed to avert accidents. Opting for a conveyor with robust safety measures not only safeguards your workforce and merchandise but also fosters a secure workplace.

As businesses increasingly prioritize sustainability, energy consumption has become a critical factor. Many Fully Automatic Conveyor systems now offer energy-efficient features such as automatic shutdowns during inactivity or variable speed motors that adapt to the load. Investing in an energy-efficient conveyor can result in significant cost savings over the long term.

Flexibility is another key attribute to consider in a conveyor system. Modular conveyors, which permit the addition or removal of sections in response to fluctuating production demands, are particularly advantageous. This adaptability is invaluable for businesses anticipating expansion or changes in their product lines, as it allows for cost-effective adjustments to your conveyor system without the need for complete replacement.

In essence, selecting an appropriate Fully Automatic Conveyor requires a comprehensive understanding of your product requirements, production pace, spatial constraints, and system controls. Focusing on durability, maintenance, safety, and adaptability will ensure that the conveyor you choose effectively bolsters your business operations. By taking these elements into account, you can identify a Fully Automatic Conveyor that enhances the efficiency of your production line and contributes to the smooth daily functioning of your operations.

English

English