What are the Three Types of Conveyors?

Conveyors are essential components in various industries, offering solutions for transporting goods, materials, and products efficiently within production lines, warehouses, and distribution centers. Among the many conveyor systems available, Fully Automatic Conveyors stand out due to their ability to operate without manual intervention, making them an ideal choice for modern industrial settings. In this article, we’ll explore the three most common types of conveyors, with a special focus on Fully Automatic Conveyors and their role in automation.

1. Belt Conveyors

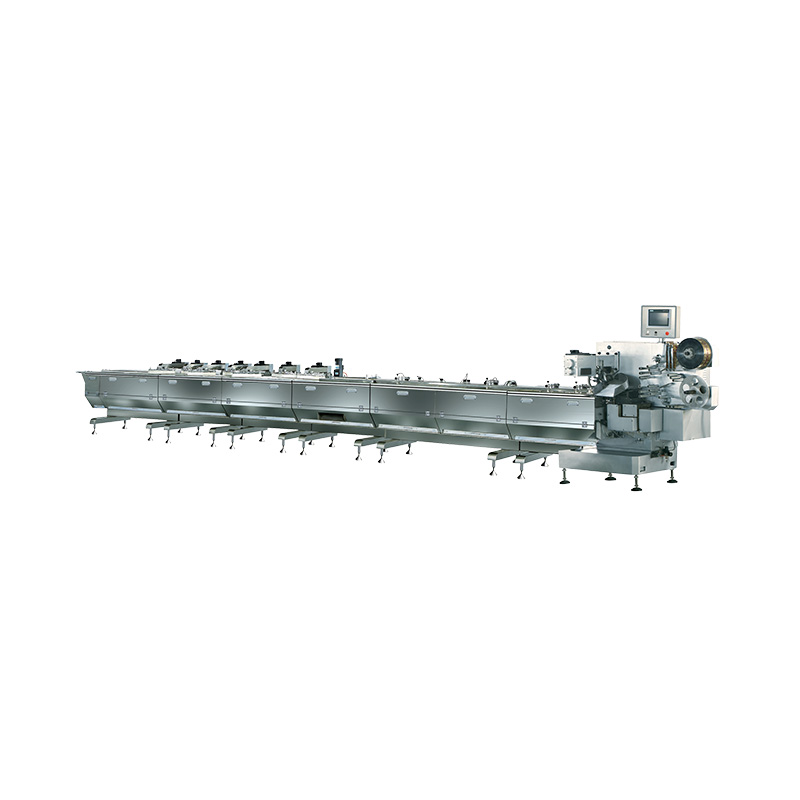

Belt conveyors are among the most widely used types of conveyors in industries that require the continuous transport of products across short or long distances. A belt conveyor operates with a continuous loop of material (typically made of rubber, PVC, or fabric), which moves around pulleys powered by motors. This design makes them ideal for transporting bulk items such as packages, boxes, and even materials like grains and coal.

Fully Automatic Belt Conveyors are particularly beneficial in manufacturing and distribution processes. They help reduce labor costs and increase operational efficiency by automatically transporting products from one part of the factory to another. Automated sensors and control systems ensure the smooth operation of these conveyors, minimizing human errors and ensuring a seamless flow of products.

2. Roller Conveyors

Roller conveyors consist of a series of rollers arranged in a line, with each roller rotating freely to allow items to move over them. These conveyors are typically used for heavier items and are favored in situations where gravity is used to assist in the movement of goods. A significant advantage of roller conveyors is their versatility in handling products of various shapes and sizes.

Fully Automatic Roller Conveyors are commonly used in warehouses, sorting centers, and distribution facilities. They are often integrated with automated control systems, allowing them to operate autonomously with minimal human intervention. These systems are often designed with sensors that detect the presence of products and ensure they move to the next stage of production or delivery, such as packaging or shipment.

3. Motorized Roller Conveyors

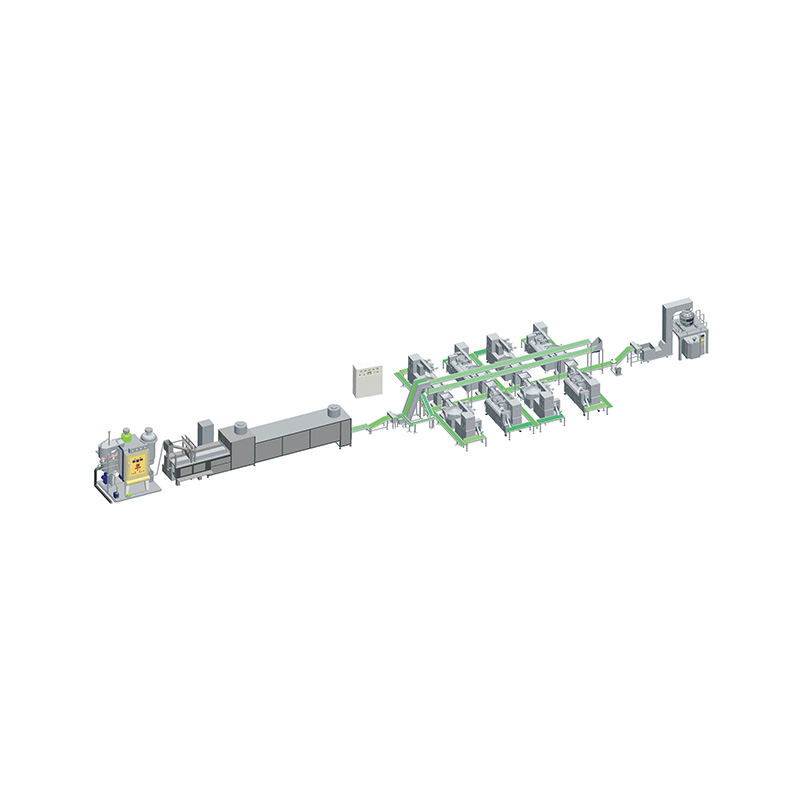

Motorized roller conveyors are similar to manual roller conveyors but include motors that drive the rollers. These systems are designed for applications that require a higher level of automation and more precise control over product flow. Motorized roller conveyors can be used in a variety of industries, including automotive manufacturing, food processing, and packaging.

Fully Automatic Motorized Roller Conveyors take automation to the next level. These conveyors are integrated with advanced control systems that can manage multiple conveyors simultaneously, synchronize product movement, and automatically adjust the speed of the rollers based on the load and requirements of the production process. They are ideal for scenarios where product sorting, merging, or accumulation is needed.

Fully Automatic Conveyor Systems: A Revolution in Efficiency

Fully Automatic Conveyors represent a significant advancement in industrial automation. These systems are designed to operate without human intervention, significantly improving operational efficiency, reducing labor costs, and enhancing the safety of the work environment. The three types of conveyors mentioned above—belt, roller, and motorized roller—can all be automated to operate seamlessly within a larger automated production or logistics system.

With the ability to monitor product movement in real-time, Fully Automatic Conveyors are often equipped with sensors, actuators, and control systems that ensure smooth and reliable operation. This makes them ideal for use in industries such as food processing, electronics manufacturing, automotive assembly, and packaging.

By integrating Fully Automatic Conveyors into a production line, companies can improve their throughput and reduce bottlenecks, allowing them to meet the growing demand for efficiency in modern manufacturing. Additionally, these systems can be customized to fit specific production needs, from handling fragile products to managing high-speed assembly processes.

Conclusion

In conclusion, conveyors come in many forms, each designed to meet specific industry needs. Whether it’s belt conveyors for simple material transport, roller conveyors for gravity-assisted movement, or motorized roller conveyors for more sophisticated automated operations, these systems help optimize the flow of goods in production lines. Fully Automatic Conveyors, in particular, play a critical role in modern industries by offering seamless automation, enhanced efficiency, and reduced human intervention, making them indispensable in today’s fast-paced manufacturing environment.

English

English