Why a Fully Automatic Conveyor Is Essential for Food, Packaging, and Logistics Lines

In today’s fast-moving world, industries like food processing, packaging, and logistics require smooth and efficient workflows to keep up with demand. A key component helping these operations run smoothly is the Fully Automatic Conveyor.

Ensuring Hygiene and Safety in the Food Industry

Maintaining hygiene and safety is a primary concern in the food industry. A fully automatic conveyor system offers a practical solution by minimizing direct human contact with food products during the production and packaging process. This reduces the potential for contamination and helps maintain consistent sanitation standards throughout the workflow.

Automatic conveyors are typically designed with materials that are easy to clean and resistant to bacterial buildup. Smooth surfaces, stainless steel components, and simple structures contribute to easier maintenance and regular sanitation procedures. These features help meet the industry's strict requirements for cleanliness.

Reducing Labor Costs and Improving Workforce Efficiency

Incorporating a fully automatic conveyor system into production lines can lead to more efficient use of labor and help reduce overall workforce costs. By automating the transportation of materials, companies can lower the number of manual handling tasks, which often require multiple workers and add to operational expenses.

With fewer workers needed for repetitive or physically demanding tasks, businesses can allocate human resources to areas that require decision-making, quality control, or technical skills. This shift not only helps control labor costs but also enhances employee productivity by allowing staff to focus on more meaningful and value-driven activities.

Flexibility in Handling Different Product Types

A fully automatic conveyor system offers valuable flexibility when dealing with a variety of product types across industries such as food processing, packaging, and logistics. This adaptability is essential in modern production environments where product shapes, sizes, and weights can differ significantly.

Automatic conveyors can be configured to accommodate different materials, from delicate items to bulk goods. Adjustable speed settings, modular designs, and customizable layouts allow manufacturers to tailor the system to specific production needs. This is especially useful in operations that frequently switch between product types or handle mixed-product batches on a single line.

Adapting to Future Industry Needs

As industries evolve, the demand for adaptable and forward-thinking solutions continues to grow. A fully automatic conveyor system supports this shift by offering the flexibility and scalability needed to meet future operational requirements. Whether in food processing, packaging, or logistics, businesses are seeking systems that can adjust alongside changing production volumes and product types.

One of the key advantages of automatic conveyors is their ability to integrate with digital monitoring tools and smart technologies. This compatibility makes it easier to implement data tracking, predictive maintenance, and real-time system adjustments—features that are becoming increasingly important in modern manufacturing environments.

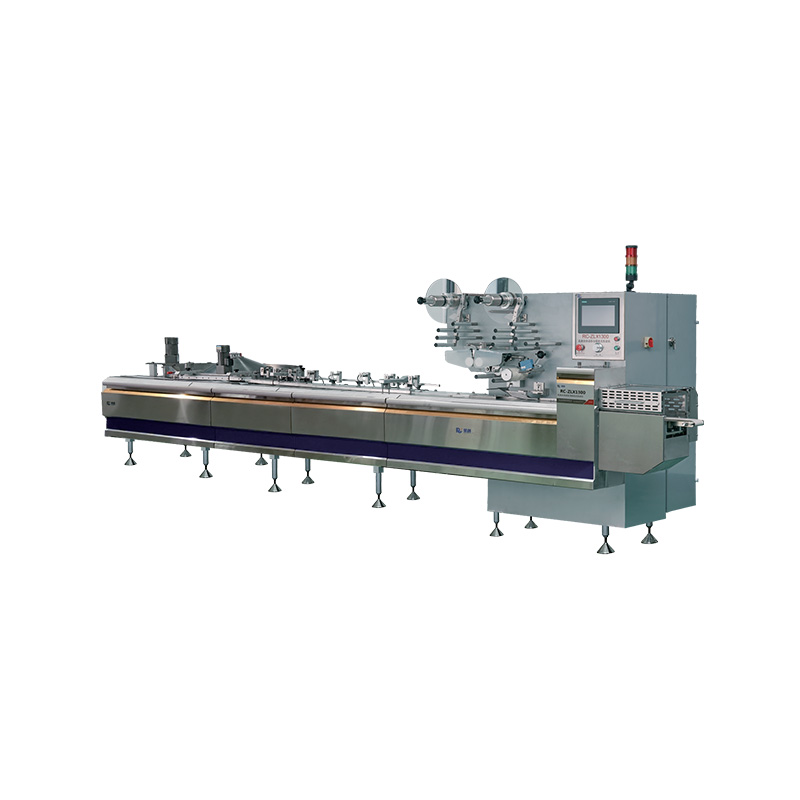

Product Recommendation: RC-ZL1300 High-Speed Fully Automatic Multifunctional Sorting Pillow Packaging Machine

For manufacturers seeking to boost packaging speed and streamline production, the RC-ZL1300 High-Speed Fully Automatic Multifunctional Sorting Pillow Packaging Machine presents an efficient and intelligent solution. Designed for high-output operations, this machine delivers performance of up to 1300 pieces per minute, making it a powerful asset in fast-paced production environments.

The RC-ZL1300 is equipped with a full-servo industrial touch screen control system, enabling a range of automated functions, including automatic material sorting, gap filling, speed adjustment, conveyor belt alignment, and cooling. These features not only improve efficiency but also reduce the need for manual intervention, helping to lower labor costs and maintain consistent packaging quality.

Its flexible design supports various packaging requirements, making it suitable for use in industries such as food, consumer goods, and logistics. Whether you're scaling up production or upgrading an existing line, the RC-ZL1300 offers reliability, precision, and ease of operation.

To learn more about the RC-ZL1300 and explore how it can support your production goals, visit the official website: https://www.zjrctech.com/

English

English