Key Features to Look for When Buying a Pillow Packaging Machine

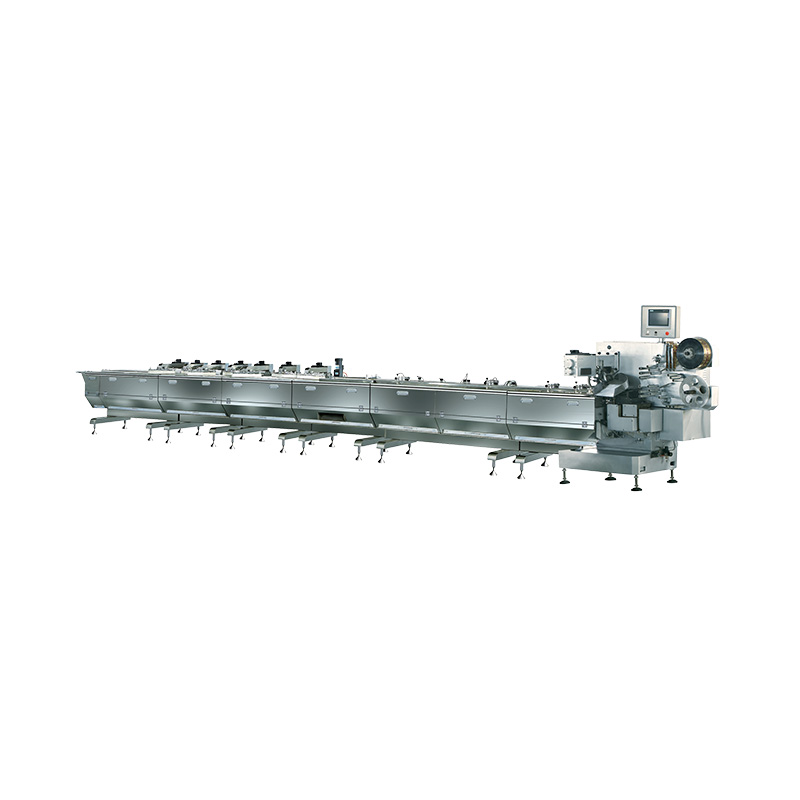

As businesses continue to expand their product lines and improve packaging standards, the demand for efficient and reliable packaging equipment has grown steadily. One type of machinery gaining attention in various industries is the Pillow Packaging Machine. Known for its ability to wrap items in a secure, pillow-shaped package, this machine is widely used for products ranging from food and pharmaceuticals to daily-use items. For manufacturers considering adding a Pillow Packaging Machine to their production line, understanding its key features is an important step before making a purchase.

A Pillow Packaging Machine is designed to package products horizontally by wrapping them in film and sealing the edges to create a compact, protective package. One of the essential features to examine when choosing a Packaging Machine is its packaging speed. While different models offer various output rates, businesses should select a machine that matches their production volume without causing delays or unnecessary downtime. A suitable speed ensures that the packaging process remains smooth and consistent throughout daily operations.

Another important aspect to consider is the size range supported by the Pillow Packaging Machine. Different industries require packaging for items of varying shapes and sizes. Some machines offer adjustable forming and sealing components, allowing operators to modify settings to accommodate different product dimensions. This flexibility is valuable for manufacturers with diverse product lines, making the Packaging Machine adaptable to changing production demands.

Ease of operation is also a key feature of a Pillow Packaging Machine. Modern machines often include user-friendly control panels with touchscreen displays, clear instructions, and simple adjustment options. These controls help operators manage settings such as temperature, packaging length, and cutting position with ease. A Packaging Machine that is easy to operate reduces the learning curve for staff and reduces the risk of errors during production.

The material compatibility of a Pillow Packaging Machine should also be assessed. Depending on the industry and product type, businesses may use different packaging films, such as plastic, laminated materials, or biodegradable films. A reliable Packaging Machine should be capable of handling various film types without affecting the quality of the seal or the overall appearance of the package.

Durability and build quality play an important role in the long-term performance of a Pillow Packaging Machine. Manufacturers should look for machines constructed with robust, corrosion-resistant materials to withstand continuous operation in different environments, including humid or high-temperature settings. Regular maintenance and ease of cleaning are also important factors that can extend the service life of a Pillow Packaging Machine.

Another feature to pay attention to is the sealing system. A high-quality Pillow Packaging Machine should offer consistent and airtight sealing to protect products from contamination, moisture, and damage during transportation. Adjustable sealing temperature controls and stable pressure systems contribute to uniform seal quality across all packaged items.

Energy efficiency is becoming increasingly important in modern manufacturing facilities. Selecting a Pillow Packaging Machine designed for reduced energy consumption can contribute to lower operational costs over time. Features such as automatic film tracking and temperature regulation help optimize power usage while maintaining consistent packaging quality.

A Pillow Packaging Machine’s integration capabilities with existing production lines should not be overlooked. Many businesses require their packaging equipment to work seamlessly with conveyors, labeling systems, and quality inspection devices. Compatibility with other machinery ensures a continuous workflow and reduces the need for manual handling, increasing overall efficiency.

Furthermore, safety features are a necessary consideration when investing in a Pillow Packaging Machine. Modern machines are typically equipped with emergency stop buttons, safety covers, and automatic shutdown systems in case of malfunctions. These features help protect operators and reduce the risk of workplace accidents during machine operation.

For businesses aiming to reduce waste, a Pillow Packaging Machine that reduces film usage while maintaining package integrity can offer both environmental and economic benefits. Precise film cutting mechanisms and adjustable package length controls help limit material waste and optimize film consumption.

English

English