What Makes Zjrctech's Packaging Systems Smarter Than Others?

In today's fast-paced manufacturing environment, packaging is no longer a simple end-of-line process. It plays a direct role in efficiency, product quality, cost management, and customer satisfaction. Companies are increasingly looking for packaging systems that do more than just seal and label products—they want solutions that adapt, optimize, and integrate with the entire supply chain.

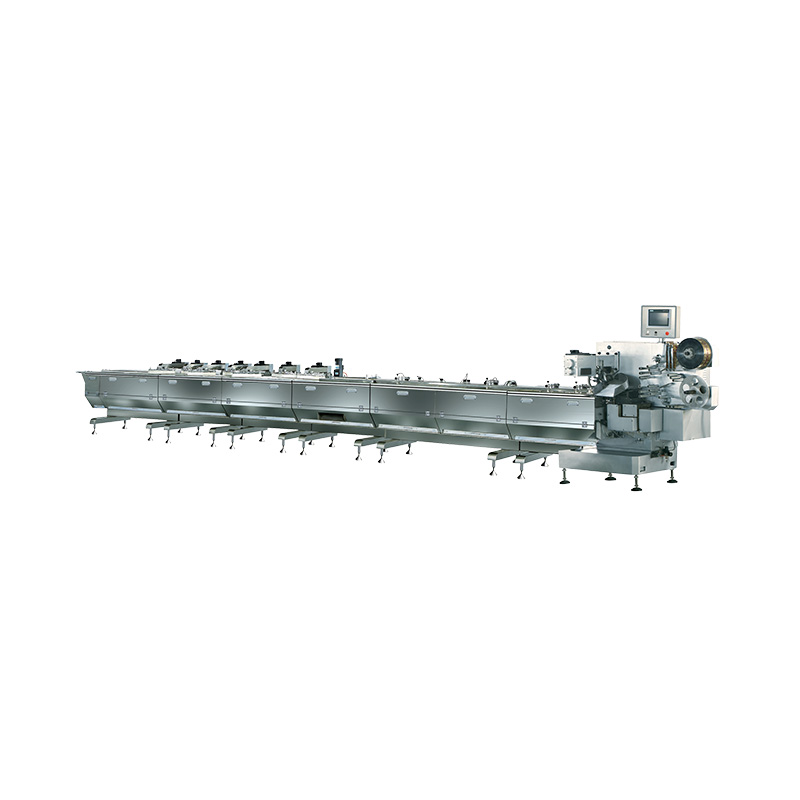

Zjrctech has developed packaging systems designed to meet these modern requirements. The focus is not on futuristic slogans, but on practical technologies that improve reliability, reduce downtime, and deliver measurable results.

1. Early Detection and Prevention

Instead of waiting for machines to fail, our systems use sensor monitoring and data models to identify small irregularities in temperature, vibration, or pressure. Detecting issues before they escalate reduces unplanned stoppages and extends equipment life.

2. Real-Time Performance Visibility

Operators and managers can access clear dashboards showing line speed, efficiency levels, and areas where adjustments may be needed. This makes decision-making faster and reduces the guesswork that often slows down production.

3. Coordinated Line Adjustments

Packaging lines often involve multiple machines working together. Our systems are designed to synchronize speed and pressure across different modules, preventing bottlenecks and ensuring smooth product flow from start to finish.

4. Predictive Maintenance Planning

By analyzing long-term performance trends, our solutions forecast when parts may need servicing or replacement. This allows maintenance to be scheduled at convenient times, reducing emergency repairs and lowering overall costs.

5. Built-In Quality Control

Sensors and vision systems continuously check sealing strength, fill levels, label placement, and package appearance. If an error occurs, the system can make immediate adjustments or temporarily isolate affected products—ensuring consistent quality without relying solely on manual checks.

6. Seamless Integration with Business Systems

Our packaging equipment can connect with ERP, supply chain, and logistics platforms. This integration ensures that production output matches order requirements, inventory updates are accurate, and delivery schedules stay aligned.

7. Practical ROI Benefits

Clients who adopt these solutions often see:

-

Reduced downtime through predictive maintenance

-

Fewer defective products and less material waste

-

Lower labor requirements for routine checks

-

Energy savings from optimized machine operation

-

Improved product consistency and customer satisfaction

8. Supporting Sustainability Goals

Smarter packaging systems help reduce overuse of materials, avoid unnecessary rework, and extend machine lifespan. By minimizing waste and improving efficiency, companies can align with environmental standards while lowering operating costs.

The strength of Zjrctech's packaging systems lies not in abstract promises, but in their ability to solve real production challenges. From predictive maintenance and quality control to system integration and sustainability, each feature is designed with measurable business outcomes in mind.

For manufacturers seeking reliable, connected, and future-ready packaging solutions, Zjrctech offers the technology and expertise to make packaging a true driver of operational success.

English

English