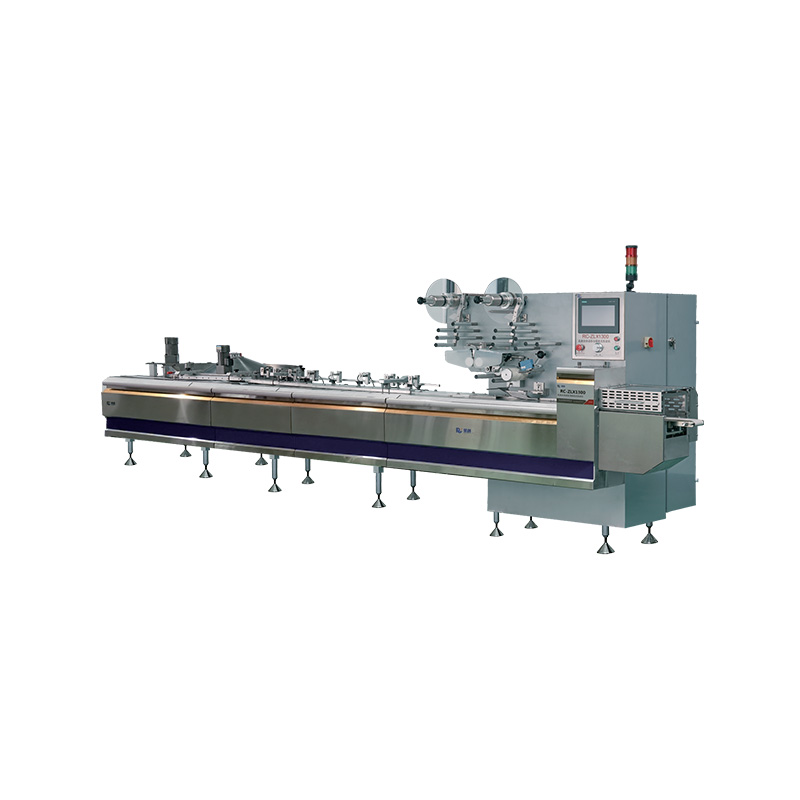

Automatic Chocolate Packaging Machine For Consistent Wrapping Efficiency

In the competitive confectionery industry, efficiency and consistency in packaging are essential to meet consumer demand and maintain product quality. The automatic chocolate packaging machine has become an increasingly valuable tool for manufacturers looking to streamline their wrapping process while ensuring uniformity in presentation and protection of the product.

A chocolate packaging machine is designed to automate the wrapping and sealing of individual chocolate bars or assorted pieces, reducing the need for manual labor and lessening human error. This mechanized approach supports higher throughput and allows manufacturers to maintain a steady production pace, which is especially important in times of high demand such as holidays and special events.

One key advantage of an automatic chocolate packaging machine is its ability to handle delicate items gently yet efficiently. Chocolates are fragile and prone to damage if not packaged carefully. Modern machines employ precise control systems and adjustable settings to accommodate various shapes and sizes of chocolate products. This adaptability makes it possible for producers to package a wide range of chocolate types, from simple bars to more complex shapes and assortments.

The consistency in wrapping achieved through automation also enhances the overall consumer experience. Uniform packaging contributes to brand identity and customer satisfaction. When every piece of chocolate is wrapped neatly with consistent tension and sealing, the product not only looks appealing but also maintains freshness longer by preventing exposure to air and contaminants.

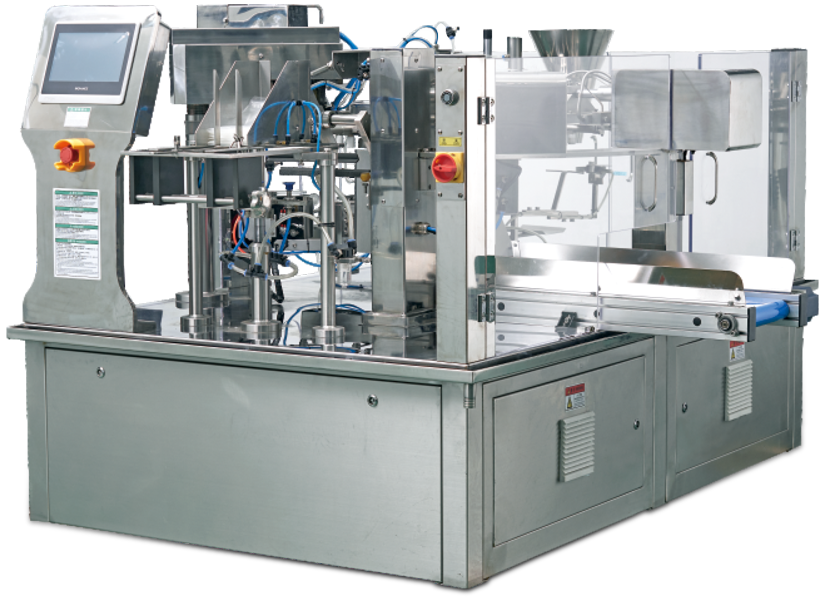

Another innovative aspect incorporated into many chocolate packaging lines is the use of robotic arms for food packaging tasks. Robotic arms add a layer of flexibility and precision to the packaging process. These programmable machines can handle picking, placing, and arranging chocolates on packaging lines with accuracy and speed that surpass manual operations. The integration of robotic arms reduces the risk of product damage and ensures that chocolates are positioned correctly before the wrapping stage.

Robotic arms can also adapt quickly to different product configurations, making them a versatile addition to a packaging system. For example, when switching from packaging individual bars to assorted boxes, robotic arms can be reprogrammed to handle the new requirements without extensive downtime. This adaptability helps manufacturers respond to changing market demands and product variations efficiently.

Beyond speed and flexibility, robotic arms contribute to improving hygiene standards in food packaging environments. Since these machines less direct human contact with the products, they reduce the chances of contamination. This is especially important in the food industry where safety regulations are strict and consumer expectations for clean, safe products are high.

Incorporating an automatic chocolate packaging machine alongside robotic arms creates a production line that balances speed, accuracy, and quality. The chocolate moves smoothly from one stage to the next—from shaping and cooling to wrapping and boxing—without unnecessary handling. This streamlined workflow helps reduce waste and ensures that packaging materials are used effectively, which can contribute to lowering operational costs over time.

Maintenance and user-friendly controls are also important considerations for manufacturers choosing packaging equipment. Many modern chocolate packaging machines come with intuitive interfaces that allow operators to monitor machine performance, adjust settings, and troubleshoot issues quickly. This ease of use supports continuous production and less downtime caused by technical difficulties.

Additionally, modular design is a feature found in many packaging machines today. This allows components such as wrapping units or feeding mechanisms to be upgraded or replaced individually. Such flexibility means the equipment can evolve alongside production needs without requiring a complete overhaul of the packaging line.

In summary, the automatic chocolate packaging machine represents a significant advancement in confectionery manufacturing by delivering consistent wrapping efficiency. When paired with robotic arms for food packaging, manufacturers gain enhanced precision, adaptability, and hygiene benefits. These technologies work together to improve productivity and product quality, helping businesses meet consumer expectations while managing production costs.

As consumer preferences and market trends continue to evolve, investing in automated and robotic packaging solutions allows chocolate manufacturers to maintain a competitive edge without compromising on the care and presentation of their products. The ongoing development of these machines promises further improvements in efficiency and flexibility, supporting the dynamic nature of the confectionery industry.

English

English