How a Twist Packaging Machine Can Boost Your Factory Output?

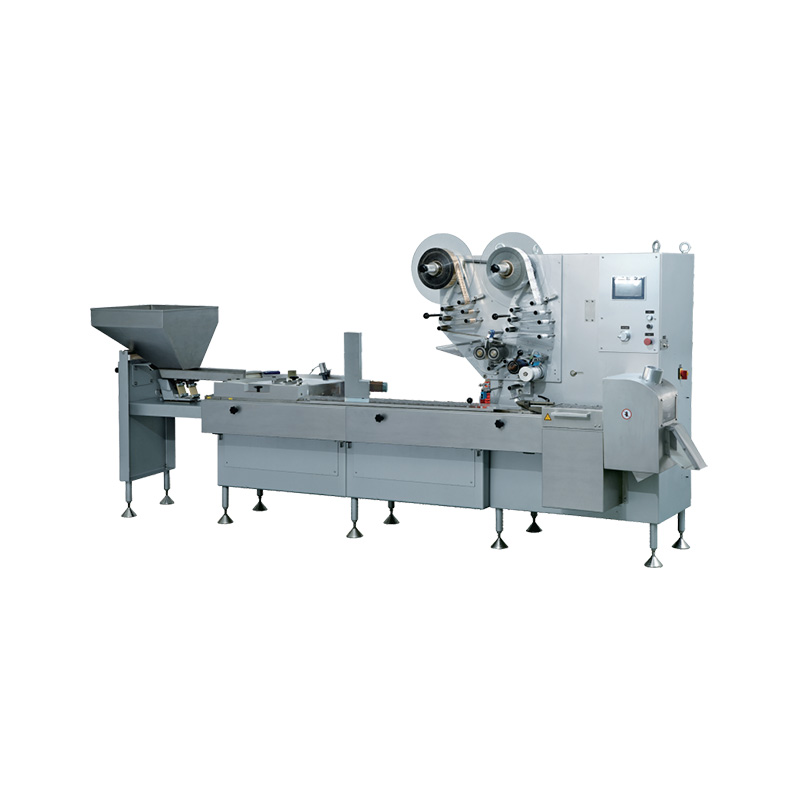

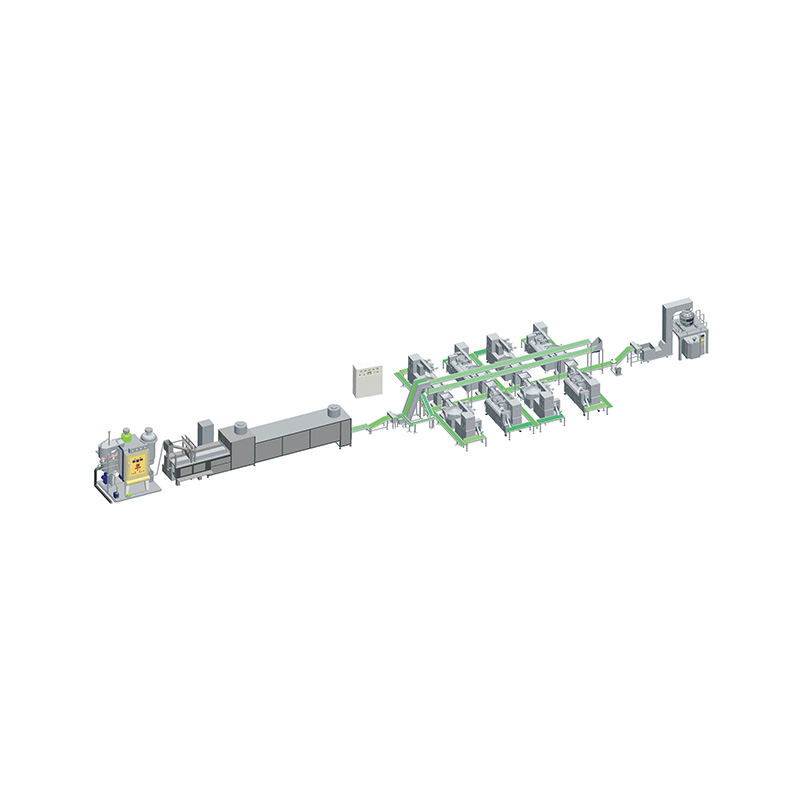

In today’s fast-paced manufacturing industry, efficiency and consistency are crucial for maintaining steady factory output. Many factories are turning to automated solutions to meet growing production demands, and one tool gaining attention is the Twist Packaging Machine. This equipment is designed to wrap products quickly and securely by twisting both ends of a packaging film, making it especially useful for confectionery, snack, and small product packaging lines.

A major reason factories invest in a Twist Packaging Machine is its ability to improve production speed. Compared to manual or semi-automatic packaging methods, this machine operates at a consistent pace, reducing the chance of delays caused by human error or fatigue. By integrating a Packaging Machine into the production line, manufacturers can maintain a steady workflow, which directly contributes to higher daily output.

The Twist Packaging Machine also enhances packaging uniformity, which is vital when handling large volumes of products. Consistent wrapping ensures that each item is securely packed and visually appealing. For factories producing candies, chocolates, or individually wrapped baked goods, a Packaging Machine helps standardize the look of every package, which can improve customer satisfaction and brand recognition.

Another advantage is the machine’s ability to accommodate different product shapes and sizes. Factories producing various items on the same line benefit from a Twist Packaging Machine because it can be quickly adjusted to suit different dimensions. This flexibility allows for smoother transitions between product types without the need for extensive equipment changes, helping to reduce downtime and maintain high output levels.

A Twist Packaging Machine also contributes to reducing material waste during the packaging process. Its precise operation ensures that only the necessary amount of film is used for each product, lowering overall material costs. By maintaining tight control over film use, factories can better manage inventory and reduce the frequency of material replenishment, keeping the production line running efficiently.

In addition to operational speed, the Packaging Machine plays a role in improving workplace organization. Automating the packaging process means fewer manual tasks for workers, which allows them to focus on other areas of production. This shift can result in smoother factory operations, clearer task division, and overall higher productivity.

Integrating a Twist Packaging Machine can also improve hygiene standards in food and snack production environments. By limiting direct human contact with products during the wrapping stage, the machine reduces the risk of contamination. This is particularly important for factories that prioritize food safety and quality assurance. Cleaner, automated packaging methods can help businesses meet regulatory requirements and improve consumer trust.

Another reason the Twist Packaging Machine is becoming popular is its compatibility with a wide range of packaging films. Factories can choose from different materials such as plastic, foil, or biodegradable wraps, depending on the product type and market preferences. This adaptability makes it easier for businesses to adjust packaging options without investing in multiple types of machinery, contributing to both flexibility and higher output.

The compact size of many Twist Packaging Machine models allows them to be integrated into existing production lines with reduced disruption. Factories with limited floor space can add this machine to their workflow without needing to redesign their entire setup. This ease of installation ensures that production improvements can be made quickly, boosting factory output without significant downtime.

Factories often face seasonal or promotional production peaks that demand increased output within a short time frame. A Twist Packaging Machine can help manage these periods by maintaining high-speed, reliable operation throughout the day. This consistent performance ensures that orders are fulfilled on time and production targets are met without overburdening the workforce.

Maintenance is another important factor to consider when aiming for continuous high output. Many Twist Packaging Machine designs are built for durability and straightforward maintenance, meaning fewer unexpected stoppages. Regular, simple servicing keeps the machine in good working condition, reducing the risk of breakdowns that could disrupt factory operations.

English

English