Why More Manufacturers Are Switching to Twist Packaging Machine Solutions?

In today’s competitive production environment, manufacturers are constantly seeking ways to improve efficiency, reduce waste, and enhance product presentation. One solution that has gained growing attention is the Twist Packaging Machine. As production demands evolve, more manufacturers across various industries are choosing this type of packaging system to streamline their operations and meet modern packaging standards.

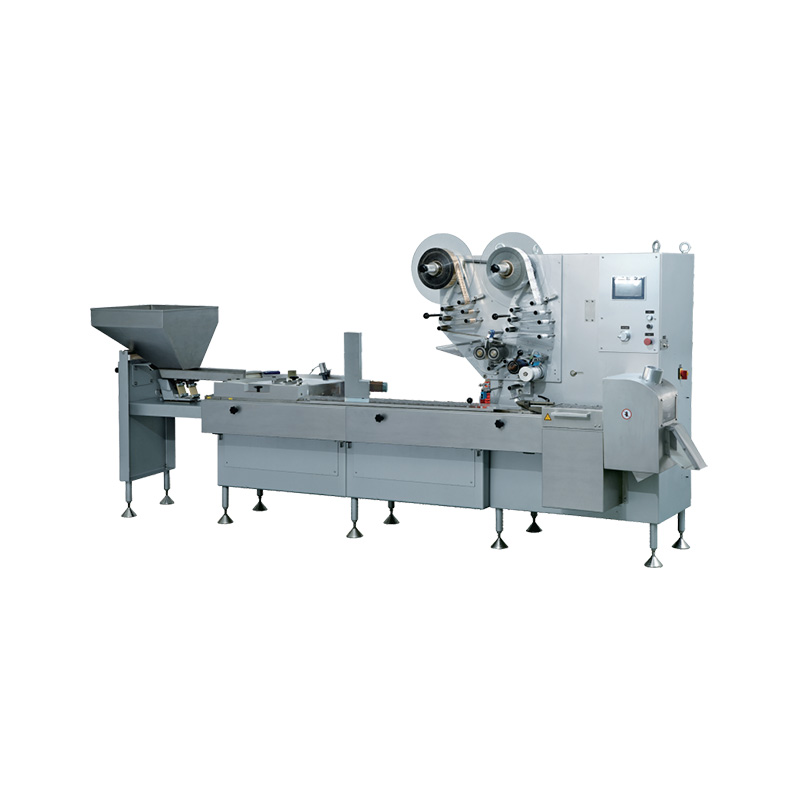

The Twist Packaging Machine is valued for its consistent and clean packaging method. It uses a twisting technique to seal the ends of packaging film around individual products, creating a secure and attractive wrap. This process is especially suitable for small to medium-sized products such as candies, snacks, and other confectionery goods. The uniform appearance created by a Packaging Machine adds value to the final product and simplifies the packaging workflow.

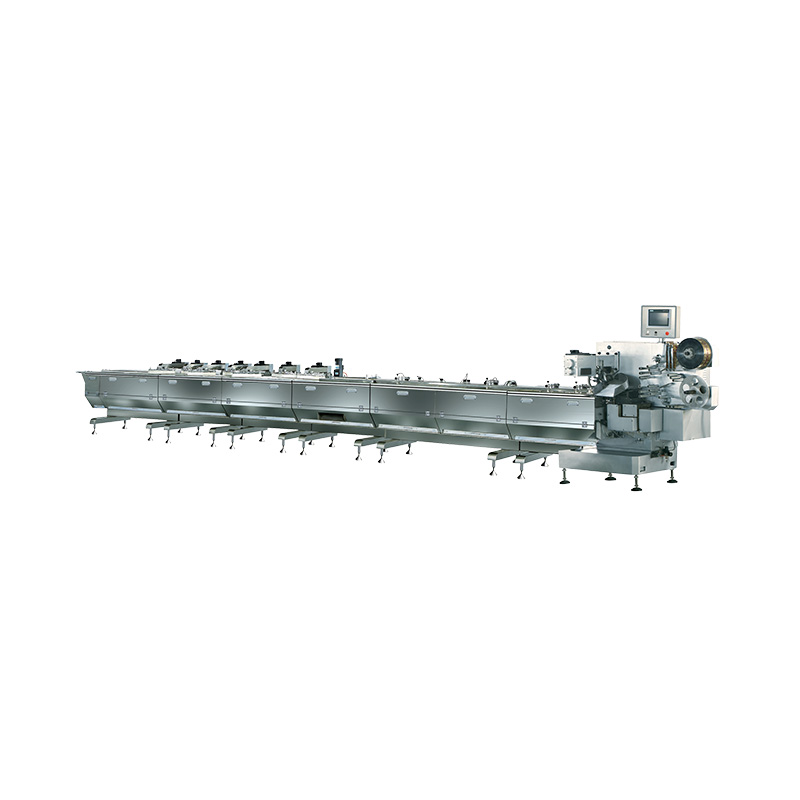

One of the main reasons manufacturers are making the switch is the Twist Packaging Machine's adaptability. It can handle different product shapes and sizes with only minor adjustments. This allows production teams to package a variety of items without needing to switch machines. Whether it’s a soft caramel or a solid chocolate piece, the Packaging Machine is capable of delivering a consistent wrap for both.

Another important factor is packaging speed. A Twist Packaging Machine can process a high volume of products in a short time, making it suitable for both small batches and large-scale production. Manufacturers appreciate the ability to maintain a steady output while keeping labor costs manageable. This packaging approach supports timely delivery schedules and helps meet increasing market demands.

The rising focus on hygiene in food and consumer product packaging has also influenced the move toward using a Twist Packaging Machine. By reducing direct human contact, the machine enhances cleanliness during the packaging process. Products wrapped using a Packaging Machine are less exposed to environmental factors, helping manufacturers maintain strict safety and quality standards.

Cost-effectiveness is another reason manufacturers are adopting this solution. The packaging materials used by a Twist Packaging Machine are generally available in various forms, such as foil, plastic, or biodegradable film. This flexibility allows businesses to select the material that matches their budget and environmental goals. In addition, the reduced material waste and lower manual labor requirements contribute to long-term operational savings.

Visual presentation is critical in retail environments. Products wrapped by a Twist Packaging Machine have a polished appearance that stands out on shelves. The twisted ends offer a recognizable and appealing finish that consumers often associate with freshness and care. Manufacturers have the option to use custom-printed films, further enhancing their branding through packaging without requiring complex machinery changes.

Some manufacturers also appreciate how easily a Twist Packaging Machine can be integrated into existing production lines. Its relatively compact size and compatibility with upstream and downstream equipment make it a practical choice for facilities with limited space. With minimal adjustments, the machine can be added to the production process to improve packaging consistency and flow.

The growing diversity of products in the snack and confectionery market also encourages more producers to invest in a Twist Packaging Machine. New product launches, seasonal items, and mixed packaging formats all require flexible solutions. The ability to change packaging film, adjust speed, and manage different product sizes makes the Packaging Machine an efficient option for these varied needs.

Manufacturers are also motivated by the simplicity of machine operation. Many Twist Packaging Machine models are designed with user-friendly interfaces, making it easy for operators to monitor and adjust packaging settings. This reduces training time and lowers the risk of production errors, which can be especially beneficial in fast-moving manufacturing environments.

English

English