How does a Twist Packaging Machine improve production efficiency in packaging

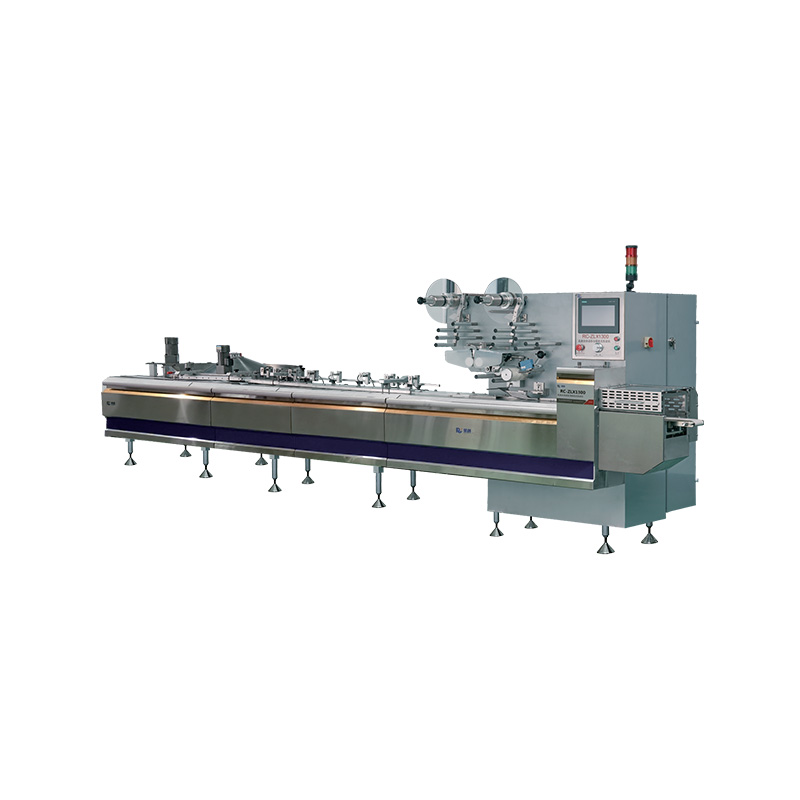

In modern manufacturing environments, factories aim to maintain consistent production while reducing repetitive manual work. A Twist Packaging Machine offers a solution that integrates automation into packaging lines. It allows products to be wrapped in a uniform manner, helping production processes operate smoothly and efficiently. By minimizing manual handling and maintaining stable workflow, this equipment supports routine operations and helps factories manage multiple product lines with minimal adjustments.

Packaging Efficiency in Production

Efficient packaging is a key factor in production management. Manual processes can introduce variability, slow movement along the line, and require additional staff. Automation ensures steady operation, reduces potential handling errors, and maintains consistent outcomes across all units.

Key aspects influenced by efficient packaging:

-

Workflow consistency: Items move without unnecessary stops.

-

Labor distribution: Operators focus on supervision and adjustments rather than repetitive tasks.

-

Material usage: Consistent wrapping reduces waste from improper handling.

-

Product uniformity: Every unit receives a similar treatment, maintaining production standards.

How the Twist Packaging Machine Supports Workflow

Automation transforms packaging by consolidating multiple steps into a single system. The machine manages feeding, wrapping, twisting, and output, reducing the need for manual intervention. Benefits include:

-

Reduced manual handling: Operators oversee the process rather than performing repetitive work.

-

Consistent wrapping: Products maintain the intended appearance.

-

Flexible operation: Adaptable for a variety of product shapes and packaging materials.

-

Flow stability: The line operates without interruptions caused by manual bottlenecks.

Manual vs Automated Packaging

| Aspect | Manual Operation | Automated Process |

|---|---|---|

| Speed | Limited by human pace | Continuous motion |

| Wrapping Consistency | Varies by operator | Uniform across units |

| Labor Requirement | Higher | Reduced |

| Material Usage | Variable | Controlled |

| Workflow Smoothness | Interruptions possible | Continuous operation |

Typical Applications

The machine is suitable for multiple manufacturing scenarios:

-

Food and confectionery: Items requiring precise wrapping.

-

Beverage packaging: Bottles or containers that need consistent covering.

-

Consumer goods: Small products with varied shapes and sizes.

-

Multiple product lines: Adaptable settings allow switching between different items with minimal adjustments.

In these applications, production can continue steadily, with less dependency on manual labor and fewer interruptions caused by inconsistent handling.

Operational Guidance

To maximize results from the Twist Packaging Machine:

-

Material selection: Use packaging materials compatible with automated handling to reduce jams or misalignment.

-

Line layout: Position the machine to minimize movement and handling time.

-

Operator training: Focus on supervision, minor adjustments, and routine checks.

-

Monitoring: Regularly observe output to ensure consistent wrapping.

-

Adjustment settings: Modify speed or tension for different products without stopping production.

Workflow with Automation

| Stage | Manual Handling | Automated Handling |

|---|---|---|

| Product Feeding | Manual placement | Conveyor or tray feeding |

| Wrapping | Hand twisting | Machine applies wrapping |

| Sealing | Manual adjustment | Automated twisting and securing |

| Transfer to Storage | Carried manually | Conveyor-assisted movement |

| Workflow Continuity | Variable | Steady motion |

Factory Scenarios

Scenario 1: Confectionery Production

Previously, staff wrapped each item by hand, leading to slight differences and slower output. After adopting the machine, wrapping became uniform, throughput was steady, and operators concentrated on overseeing output and making adjustments.

Scenario 2: Beverage Line

Multiple container sizes were difficult to manage manually. Automation allowed a continuous line without stopping for changes, producing consistent wrapping with minimal operator intervention.

Scenario 3: Small Consumer Goods Factory

Variety in product shapes required different wrapping techniques. With automation, the line handled different items with standard settings, reducing complexity and ensuring uniform packaging.

Key Advantages

- Consistent production flow: Line movement remains steady.

- Reduced manual operations: Operators supervise rather than perform repetitive tasks.

- Adaptable settings: Supports multiple product types.

- Controlled material usage: Waste is minimized by consistent handling.

- Improved uniformity: Packaging remains consistent across all units.

Efficiency Comparison

| Metric | Before Automation | After Automation |

|---|---|---|

| Packaging Flow | Variable | Steady |

| Operator Workload | High | Reduced |

| Wrapping Consistency | Inconsistent | Controlled |

| Material Waste | Variable | Limited |

| Line Stability | Moderate | Maintained |

A Twist Packaging Machine is a practical solution for modern factories aiming to maintain steady production, reduce manual handling, and standardize wrapping across multiple product lines. By automating feeding, wrapping, twisting, and output, factories can achieve stable operation, maintain consistent product presentation, and manage diverse production needs efficiently.

English

English